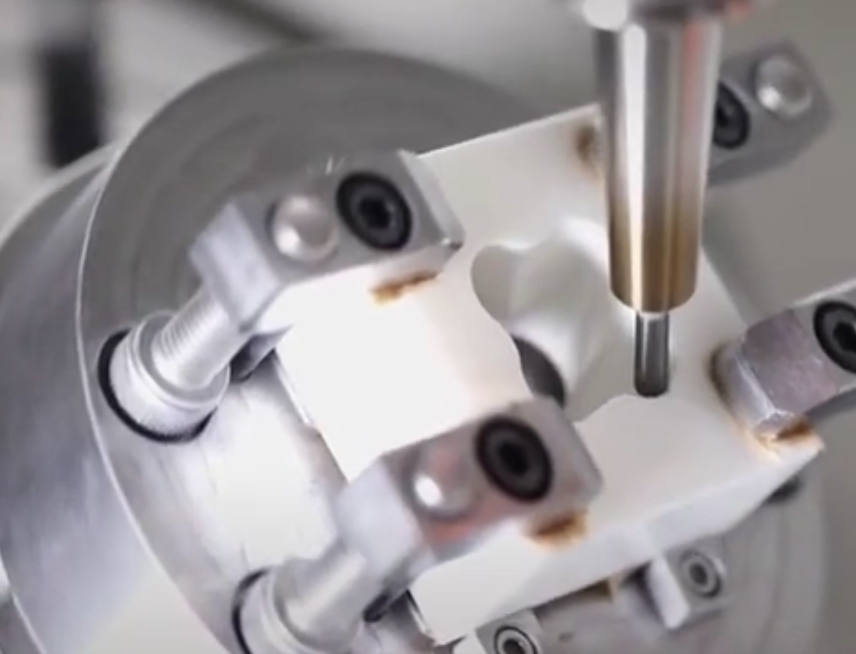

Precision Machining

We give shape to ceramics.

For a ceramic component to function properly, it is imperative to give it the exact form of the clients’ specifications. As a ceramic material specialist, we know perfectly it’s extremely “hard” to machine ceramics to accurate and complex forms. Multiples CNC, grinding and milling machines are required successively to achieve the final results. We are pound that many clients continuously entrust us for the high accuracy and few defects.

Accuracy capacity examples:

- Shaft: roundness 0.002 mm, concentricity 0.002 mm, smoothness Ra0.1

- Hole: the minimum machining diameter is 0.2 mm, and the depth can reach 6 mm (depending on the material)

- Grooves (slots): can process 0.1mm narrow grooves and various shapes

- Plate: the minimum thickness can be 0.1MM, the parallelism 0.001mm, the measurement tolerance 0.001mm, surface finish Ra0.1

- Thread: the smallest can be processed M2 internal thread, the size of the external thread is not limited