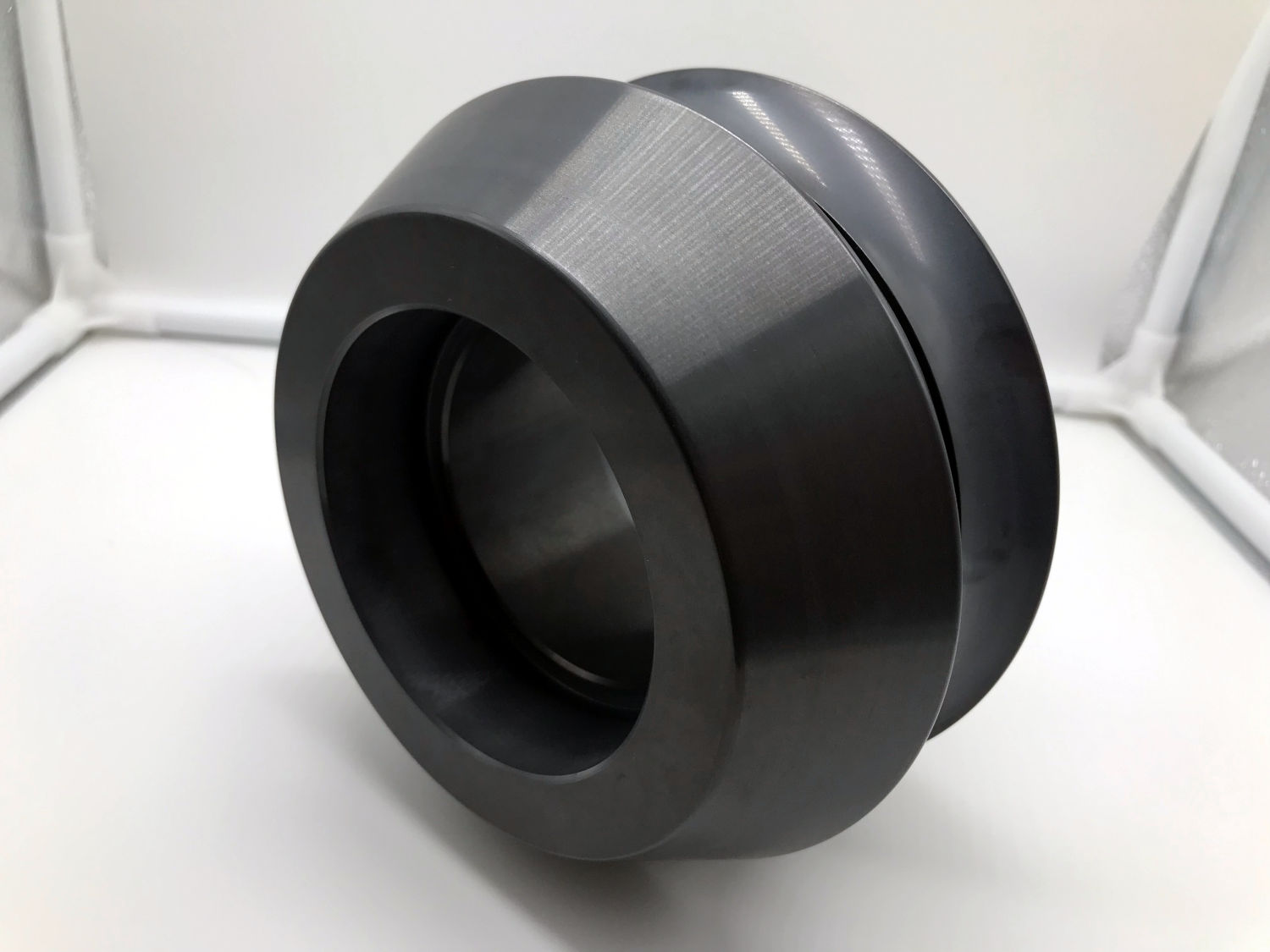

Silicon Nitride (Si3N4)

Silicon nitride ceramic has low thermal expansion coefficient, high thermal conductivity and excellent thermal shock resistance. In the very high temperature, silicon nitride keeps a high strength and impact resistance. As an excellent high temperature engineering materials, silicon nitride ceramics are “super hard” providing a high mechanical strength, outstanding wear and very good acid /alkali corrosion resistance. The material is self lubricated.

Applications

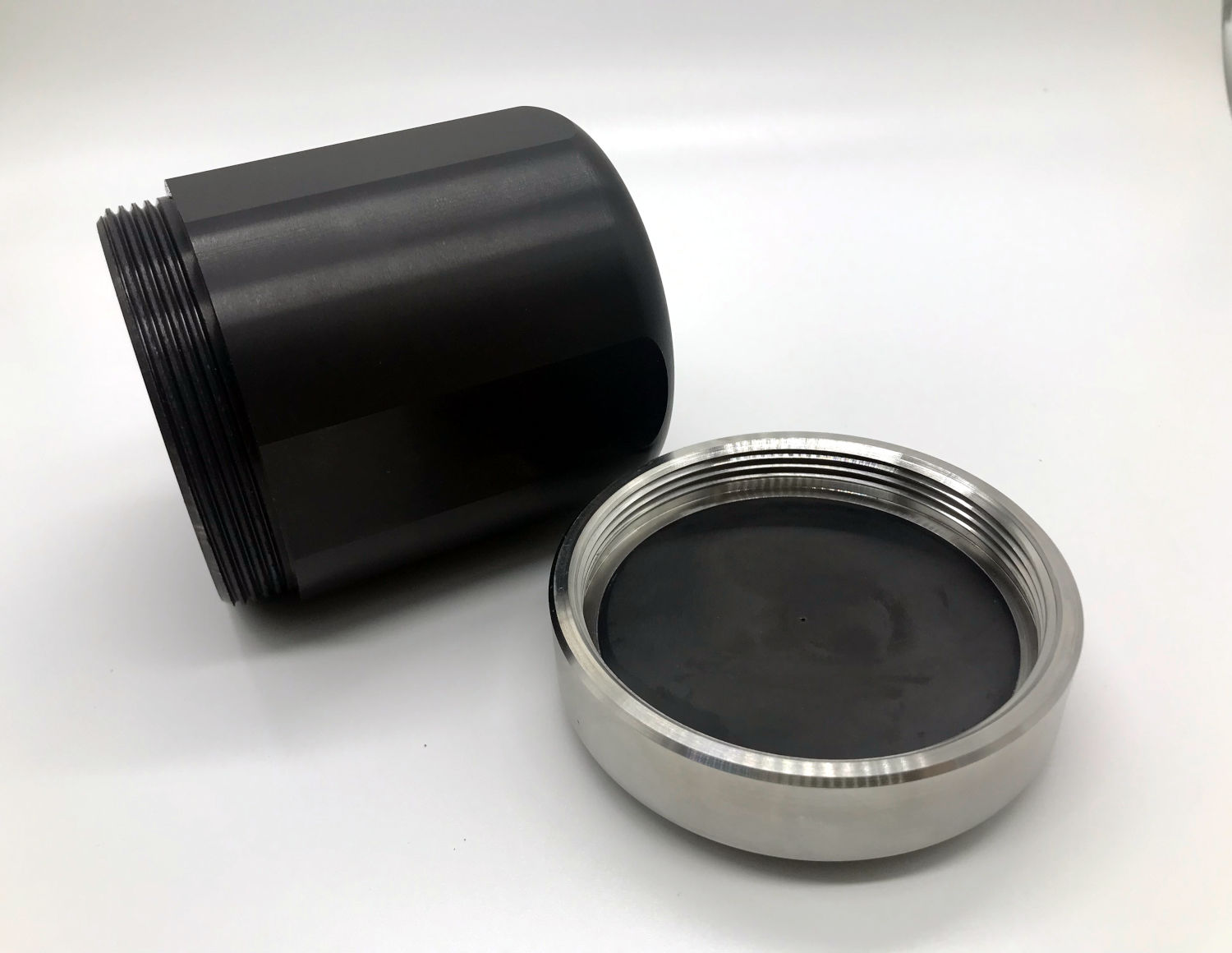

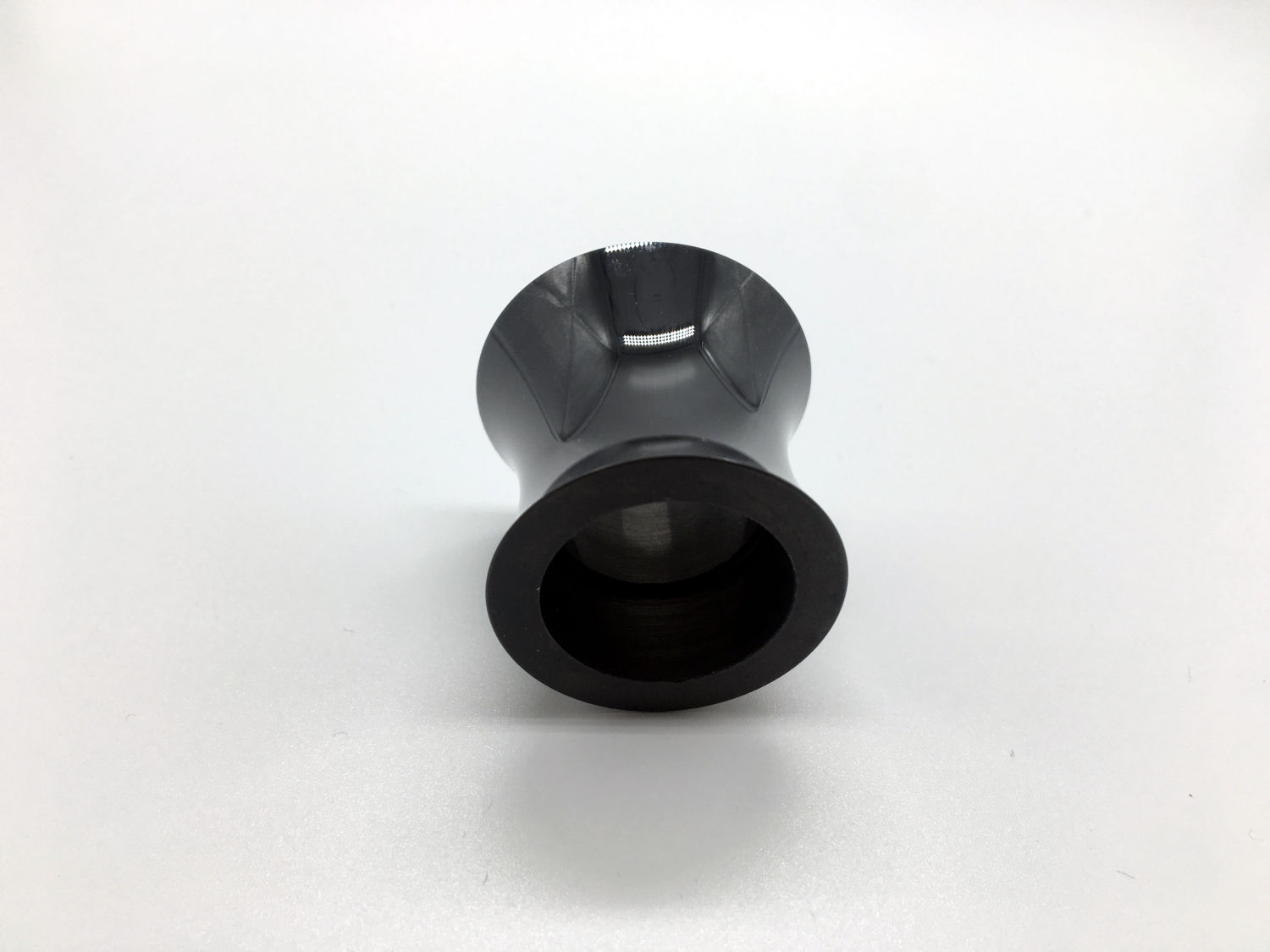

- Low-pressure cast aluminum industry: heating body protection tube, lift tube

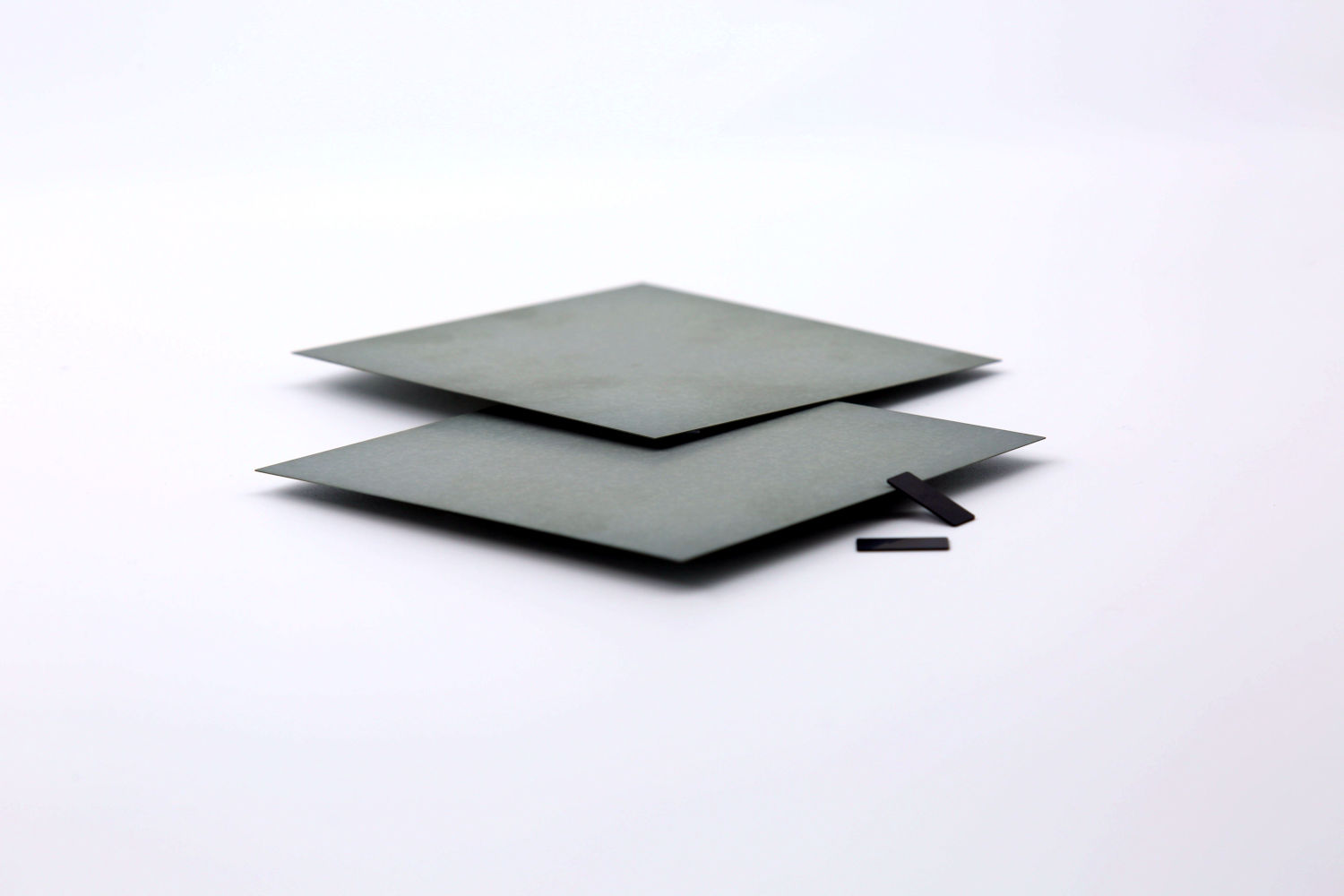

- The photovoltaic industry: long crystal crucible, exhaust hood, heat shield

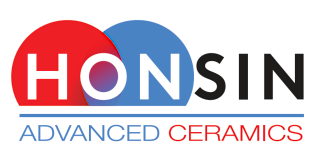

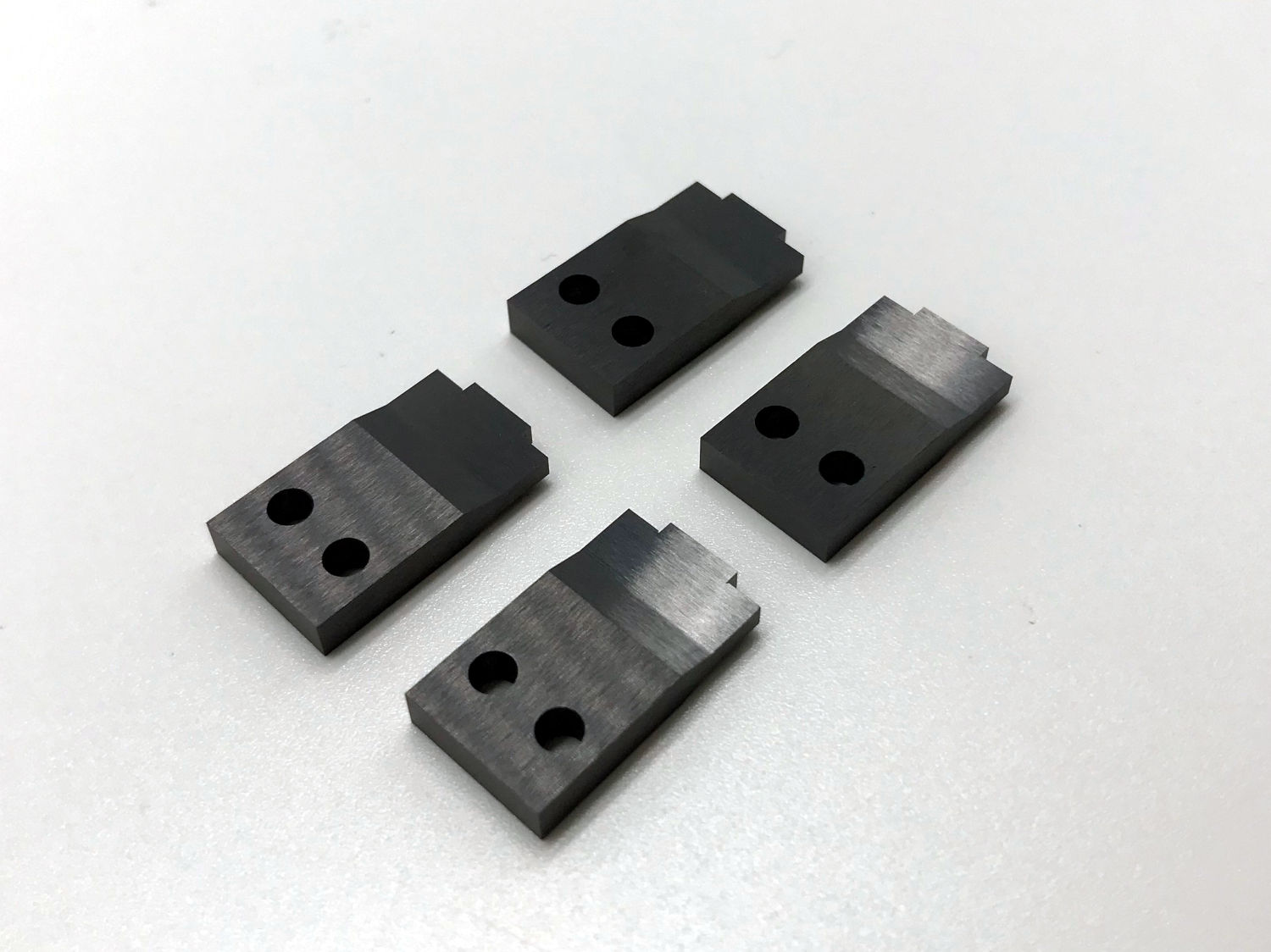

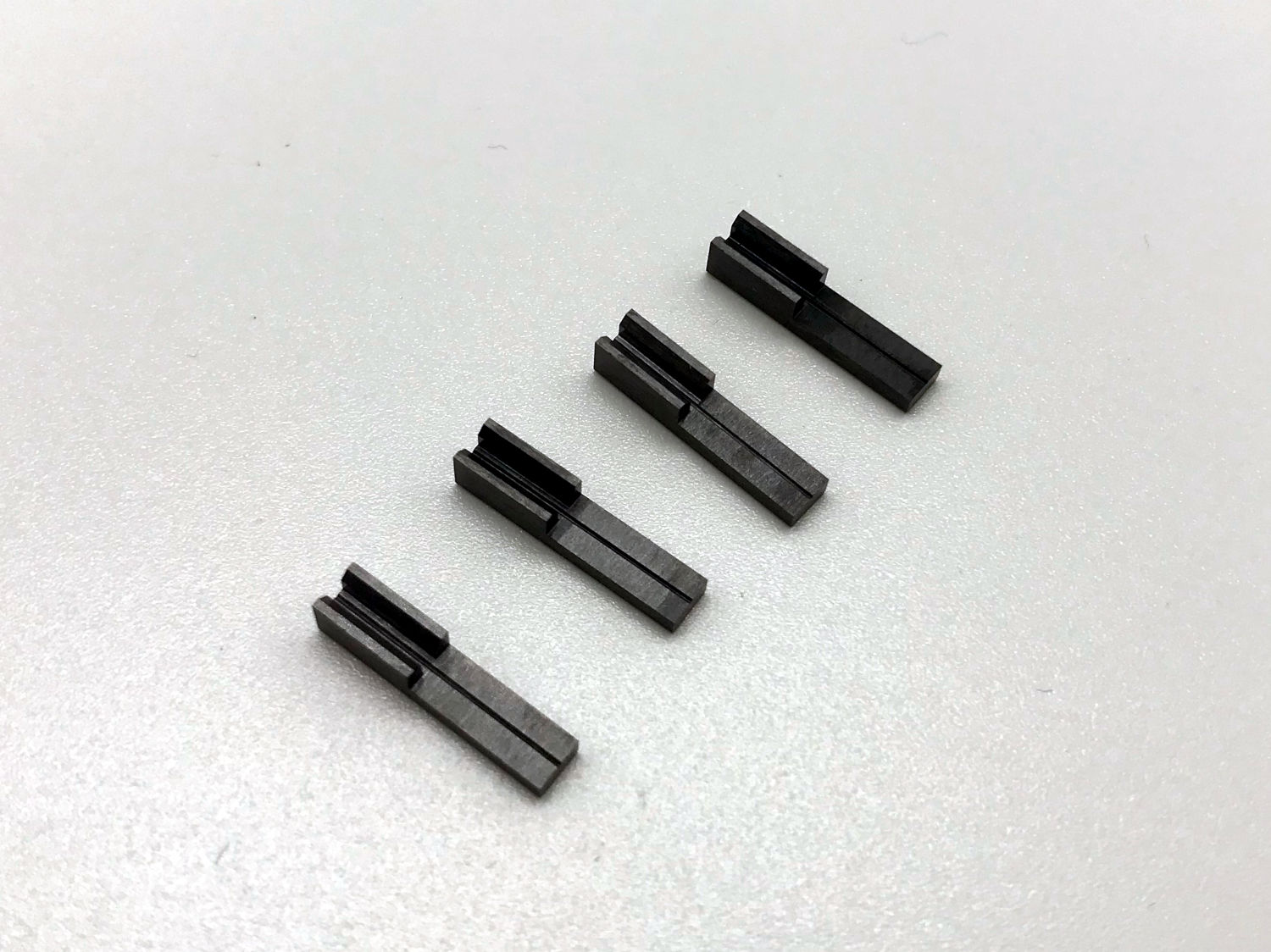

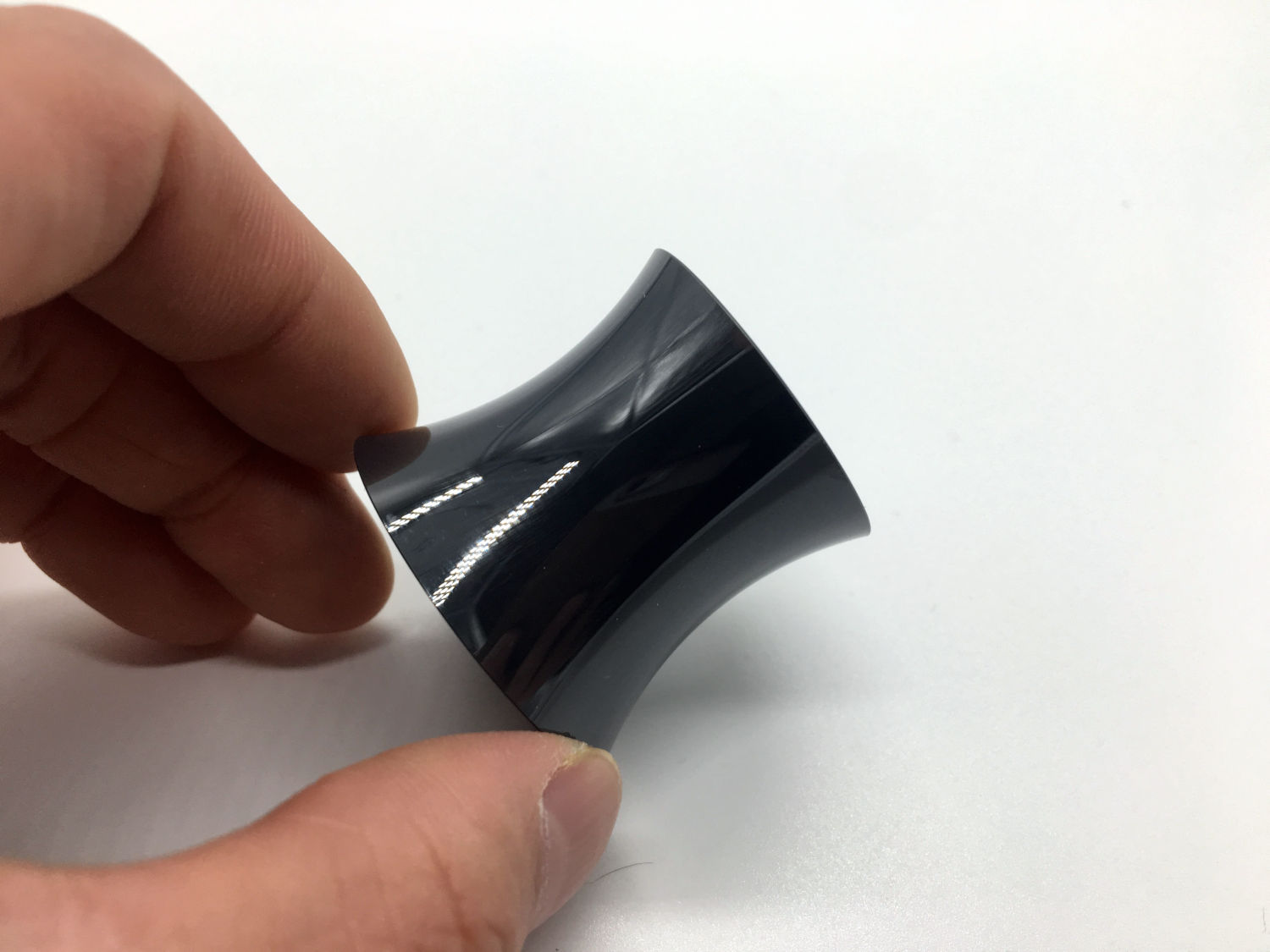

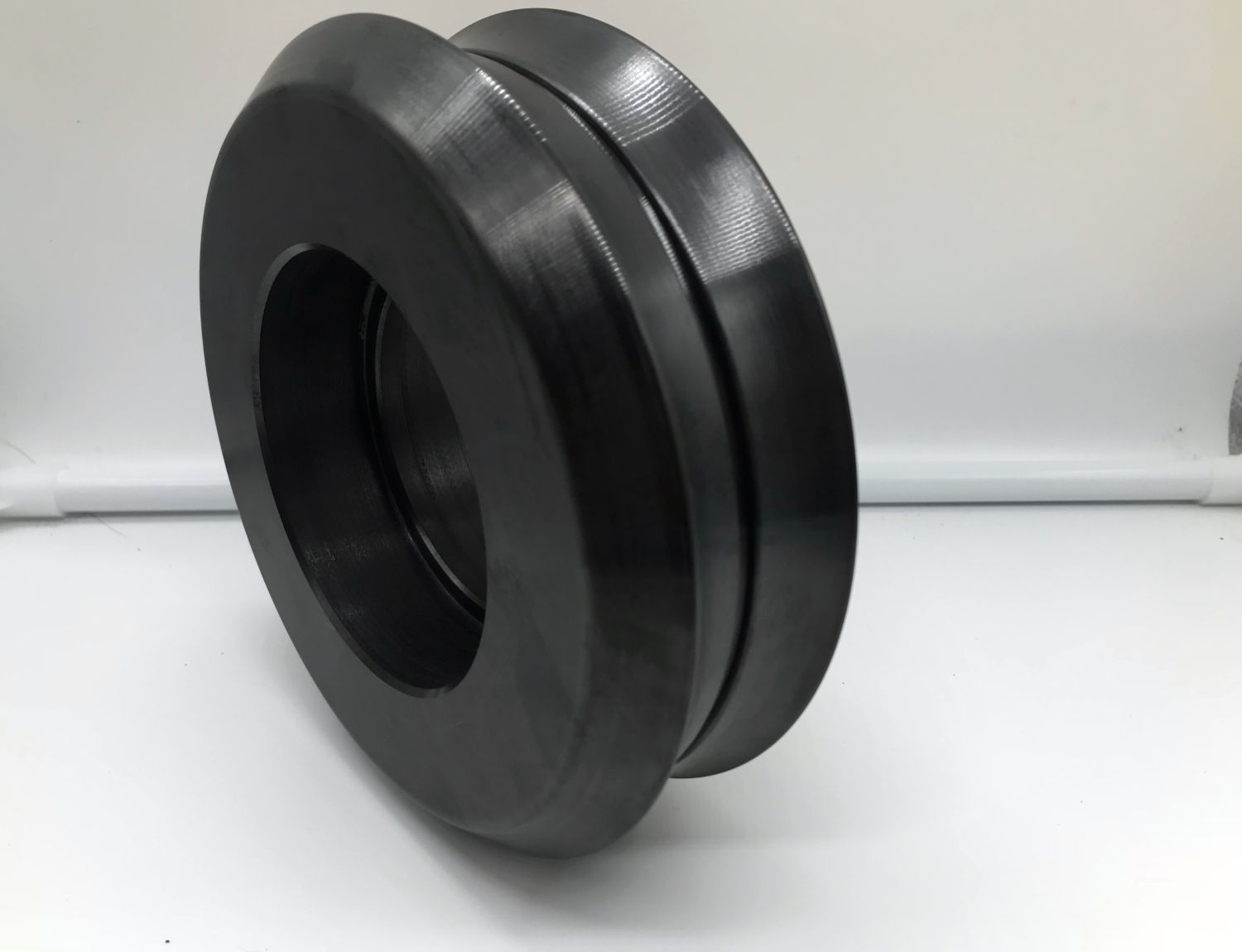

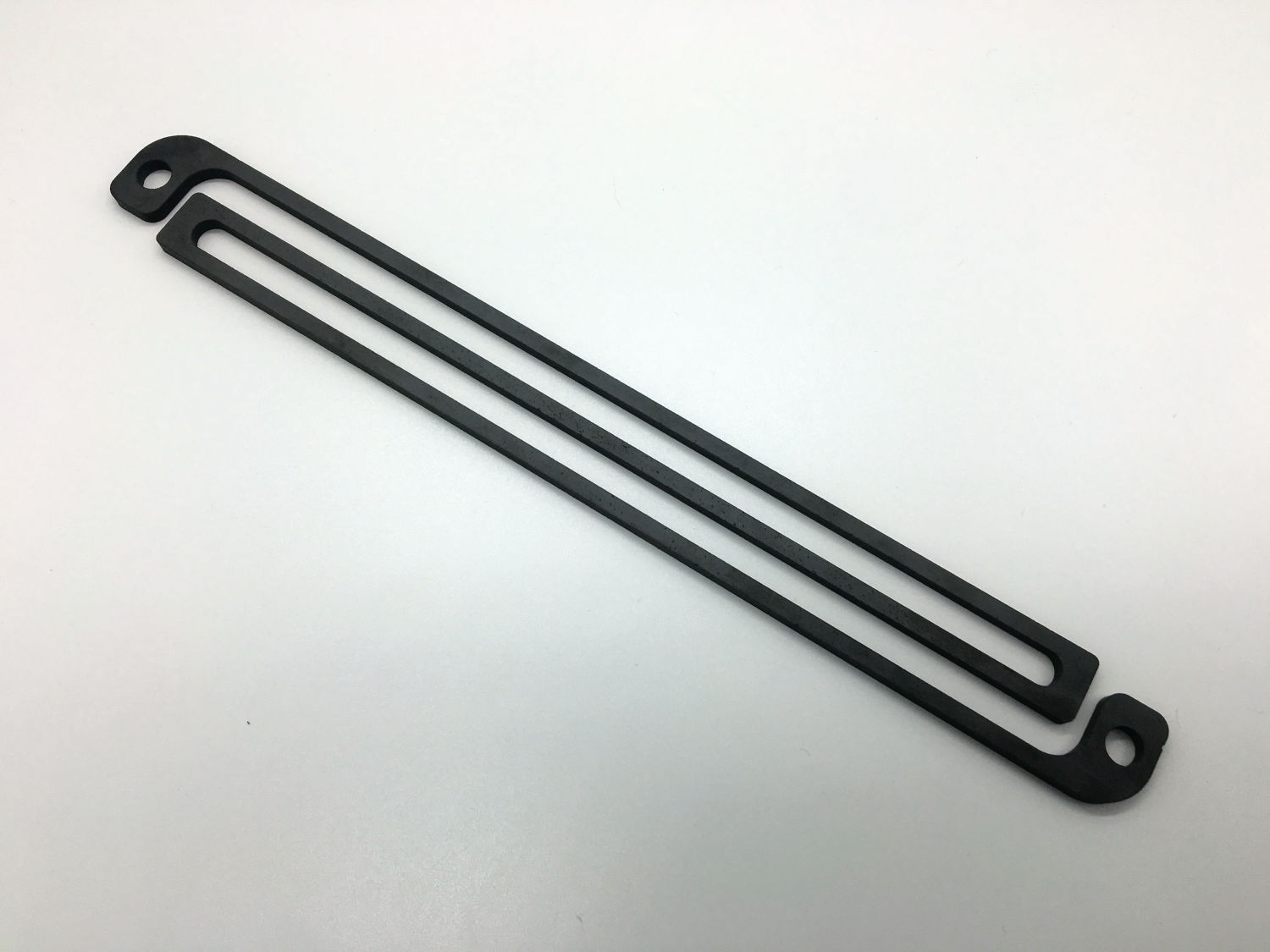

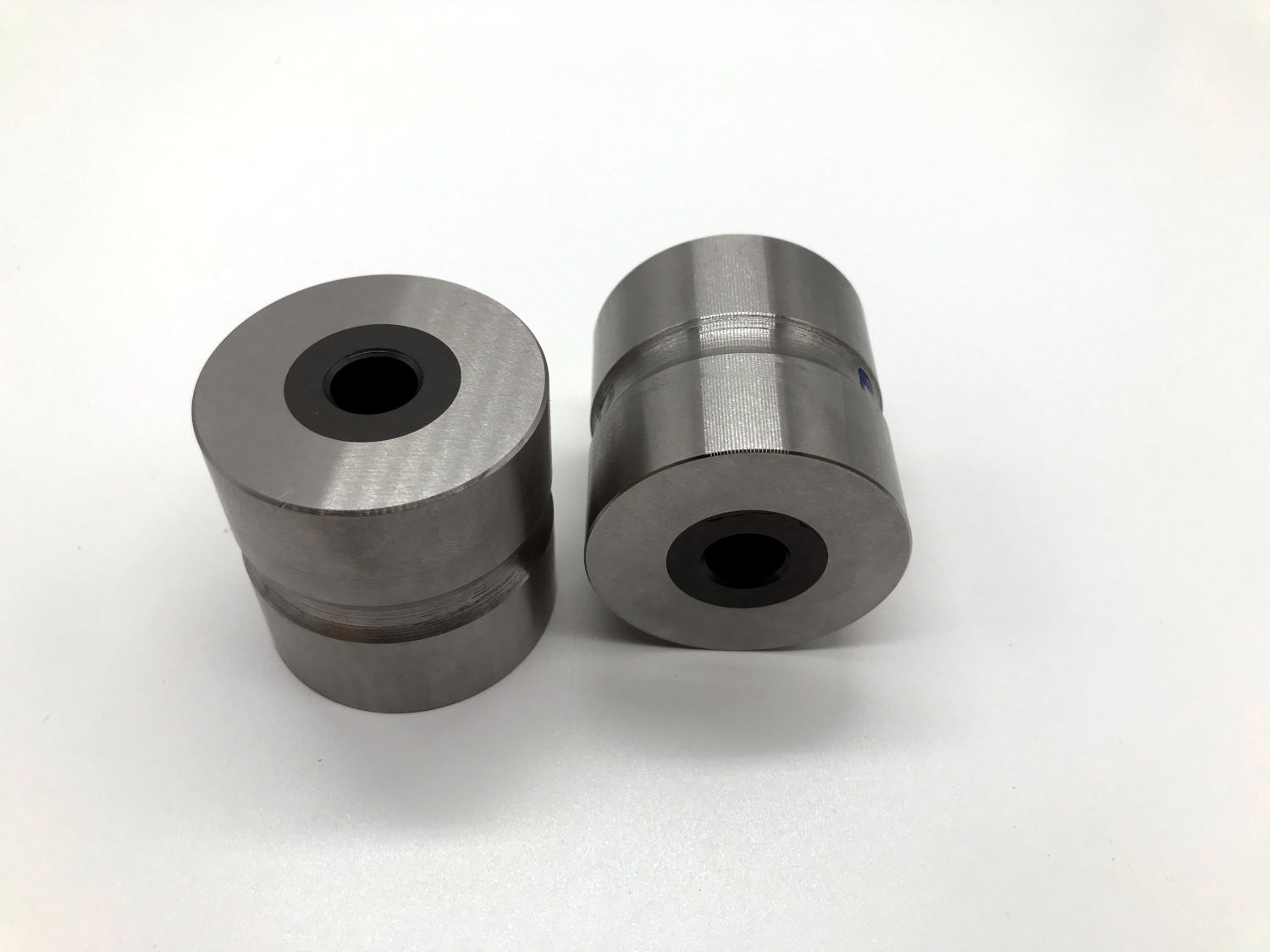

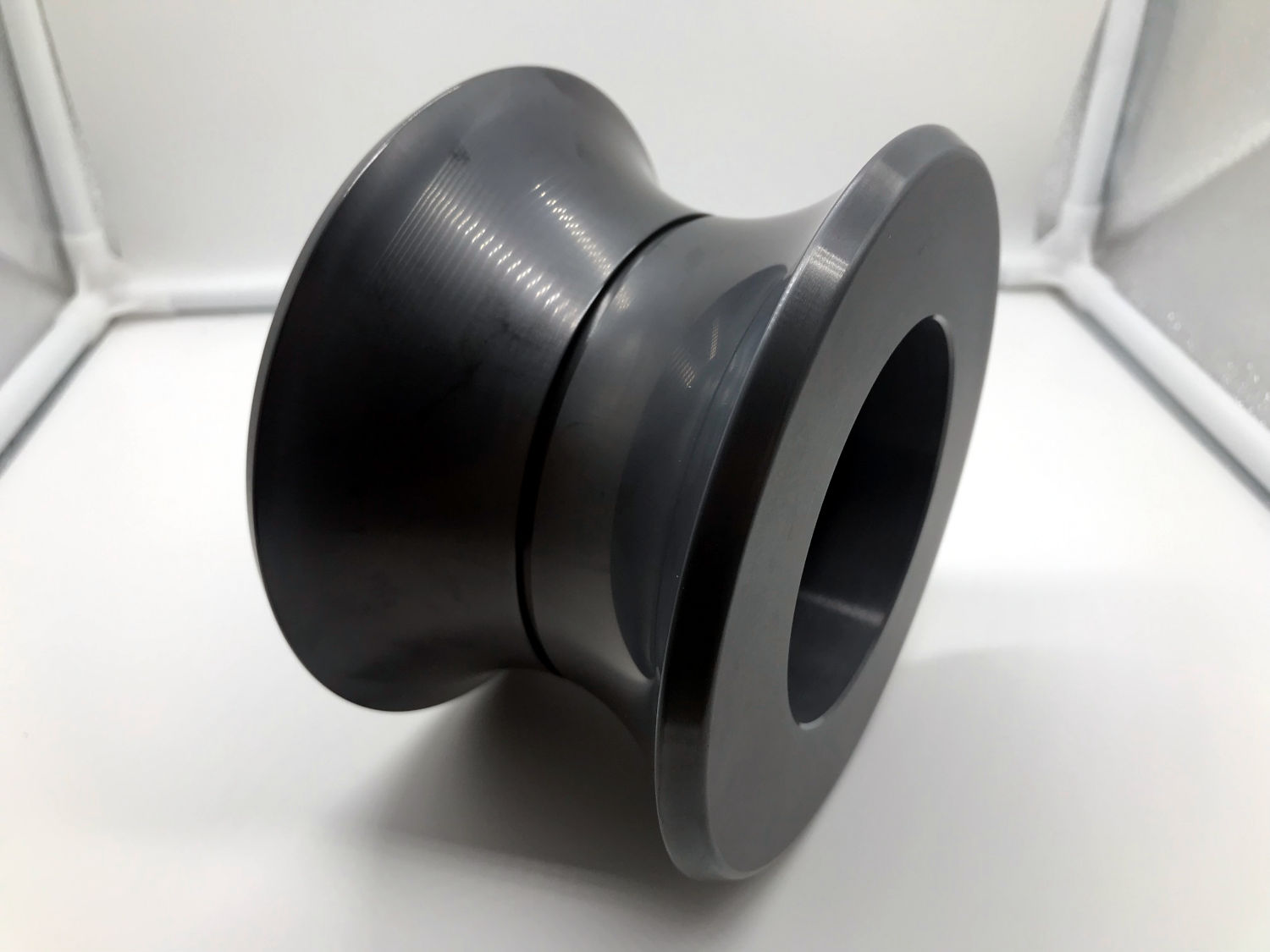

- The bearing industry: precision bearings ball, roller

- Others: mold holder, fusion furnace support, crucible rack, nozzle, insulation ring etc…

Advantages

- High mechanical strength

Silicon nitride keeps high mechanical strength over a wide temperature range. The outstanding strength characteristics with relatively low density make it easy to handle compared to conventional materials.

- Chemical stability

Silicon nitride is inert against molten metal even at high temperatures. It ensures longer work-life with minimum maintenance.

- Superior thermal shock resistance

Silicon nitride has exceptional high thermal shock resistance – making it ideal for applications with high dynamic stresses, thermal rigor, and demanding reliability requirements

Technical Characteristics – Silicon Nitride (Si3N4)

| High purity Si3N4 | HS-100 | HS-200 |

| Color | Grey | Black |

| Porosity | ≤0.4 | ≤0.4 |

| Density(g/cm3) | 3.2 | 3.2 |

| Elastic Modulus(GPa) | 320 | 300 |

| Flexural strength Room(MPa) | 780 | 700 |

| Poisson’s ratio | 0.26 | 0.26 |

| Hardness (Hv) | 1800 | 1500 |

| Thermal expansion(10-6/K) | 3.1 | 3.2 |

| Thermal Conductivity (W/m•K) | 20 | 35 |

| Max. operating temperature Air (℃) | 1200 | 1200 |

| Max. operating temperature Inert Gas (℃) | 1500 | 1500 |

| Thermal shock resistance (K) | 600 | 700 |

| Resistivity(Ω•cm) | >1014 | >1014 |

| Corrosion resistance | Good | Good |