Zirconium Oxide (ZrO2)

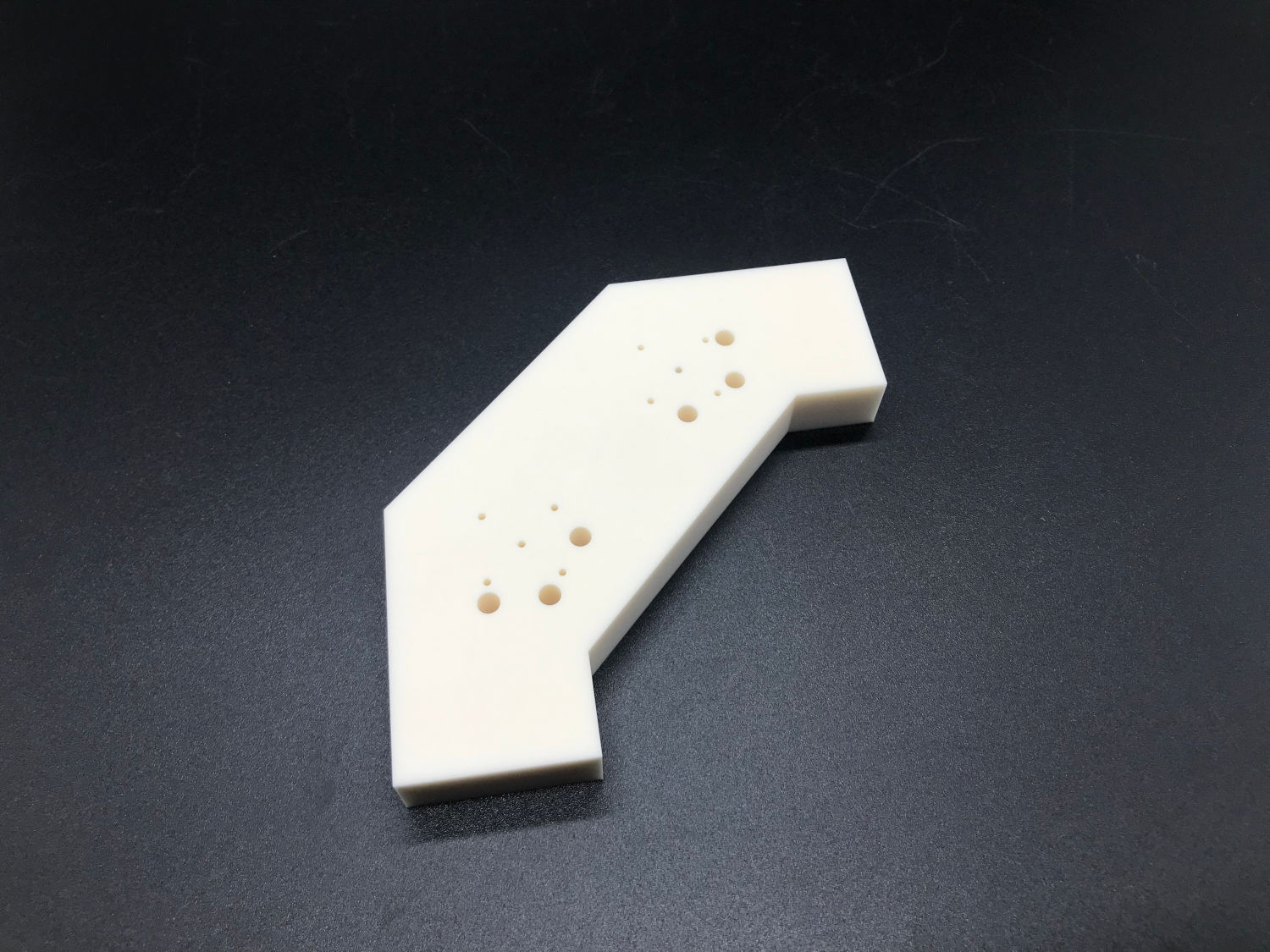

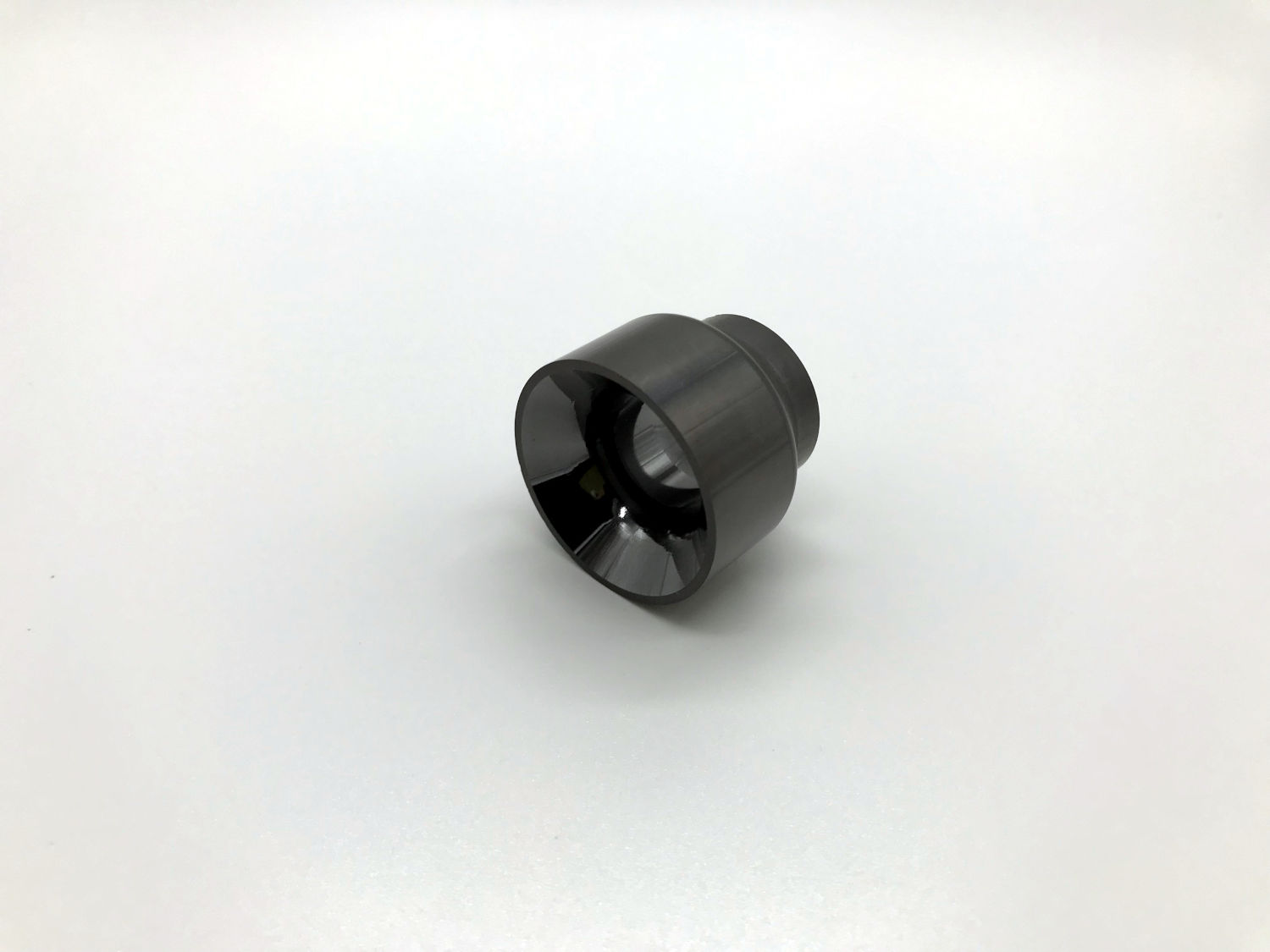

Zirconium oxide ceramic materials provide excellent erosion, corrosion and abrasion resistance along with temperature resistance, fracture toughness and strength. These ceramic components are used in extreme service applications that take advantage of their superior wear and corrosion resistance. Its fine grain size enables excellent surface finishes and the ability to hold a sharp edge.

Although it retains many properties including corrosion resistance at extremely high temperatures, Honsin zirconium oxide ceramic products include Y-PSZ, Mg-PSZ, which are widely used in many fields such as grinding media, precision analysis instruments, electronics, engineering machinery, textile machinery, chemical carrier etc…

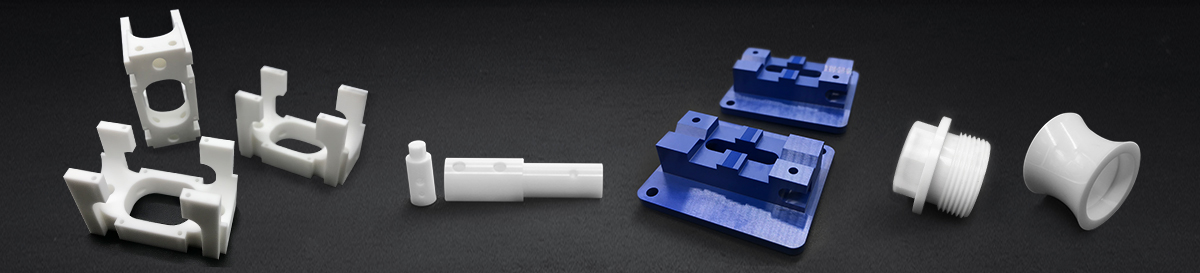

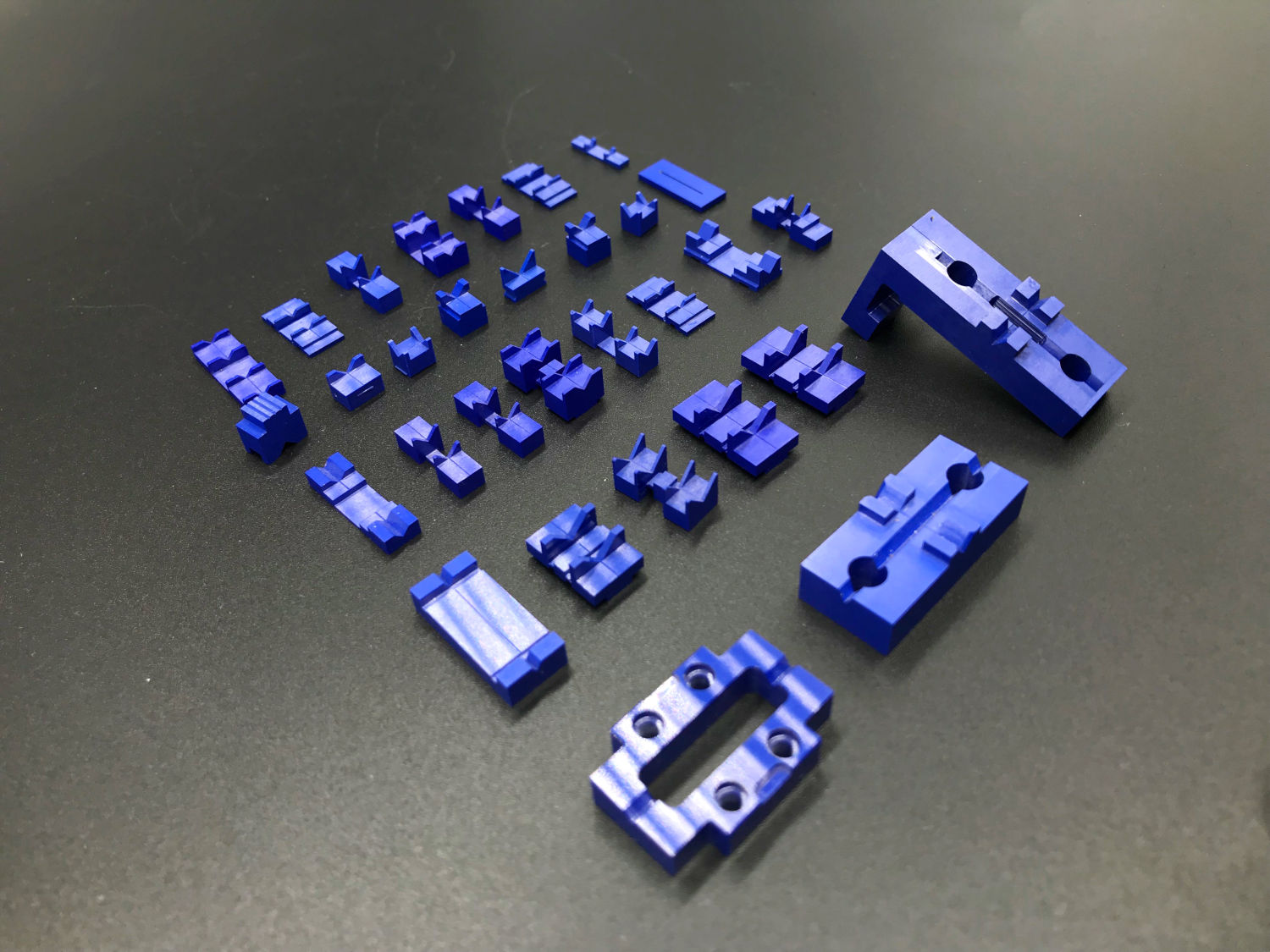

Applications

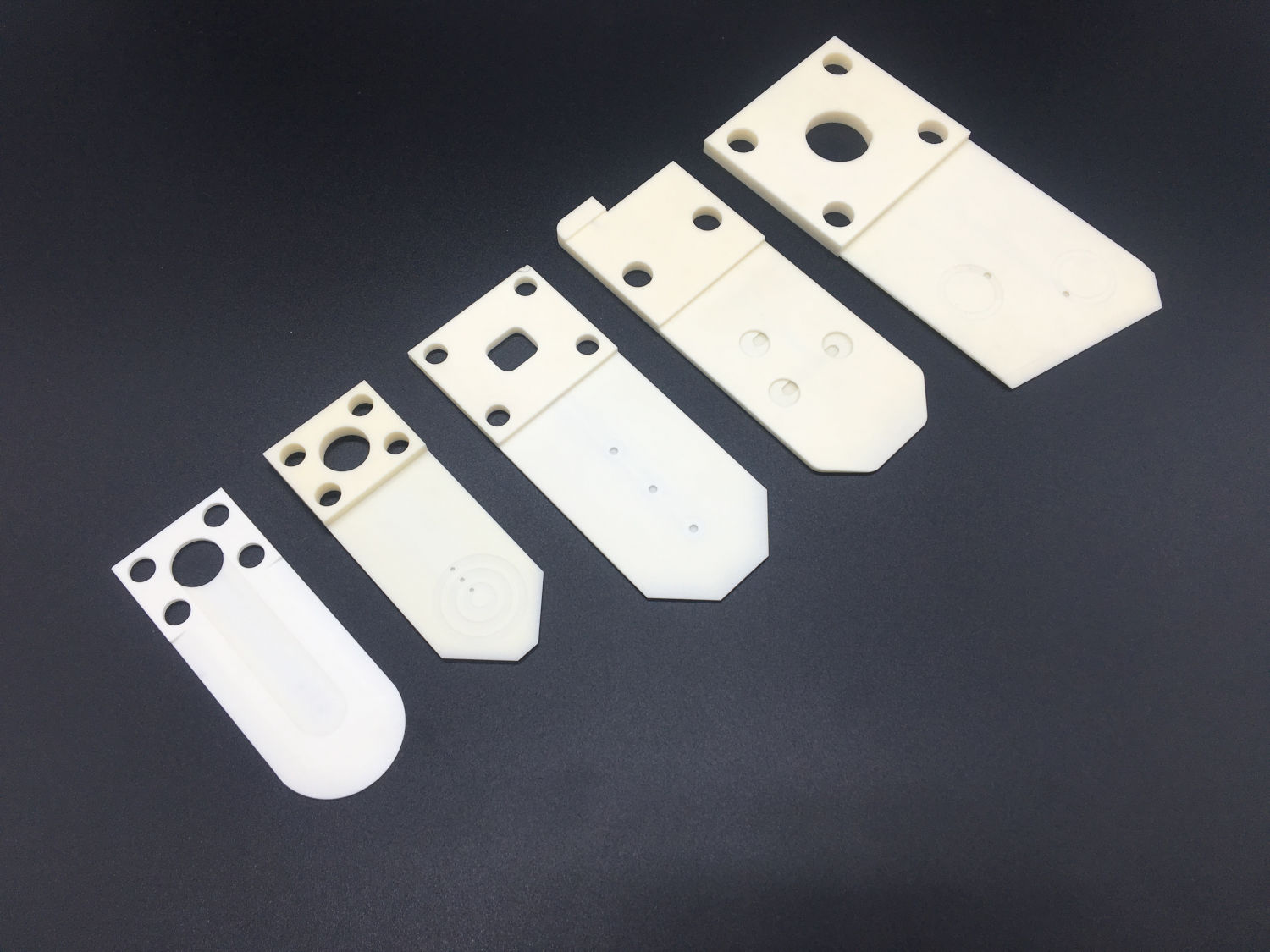

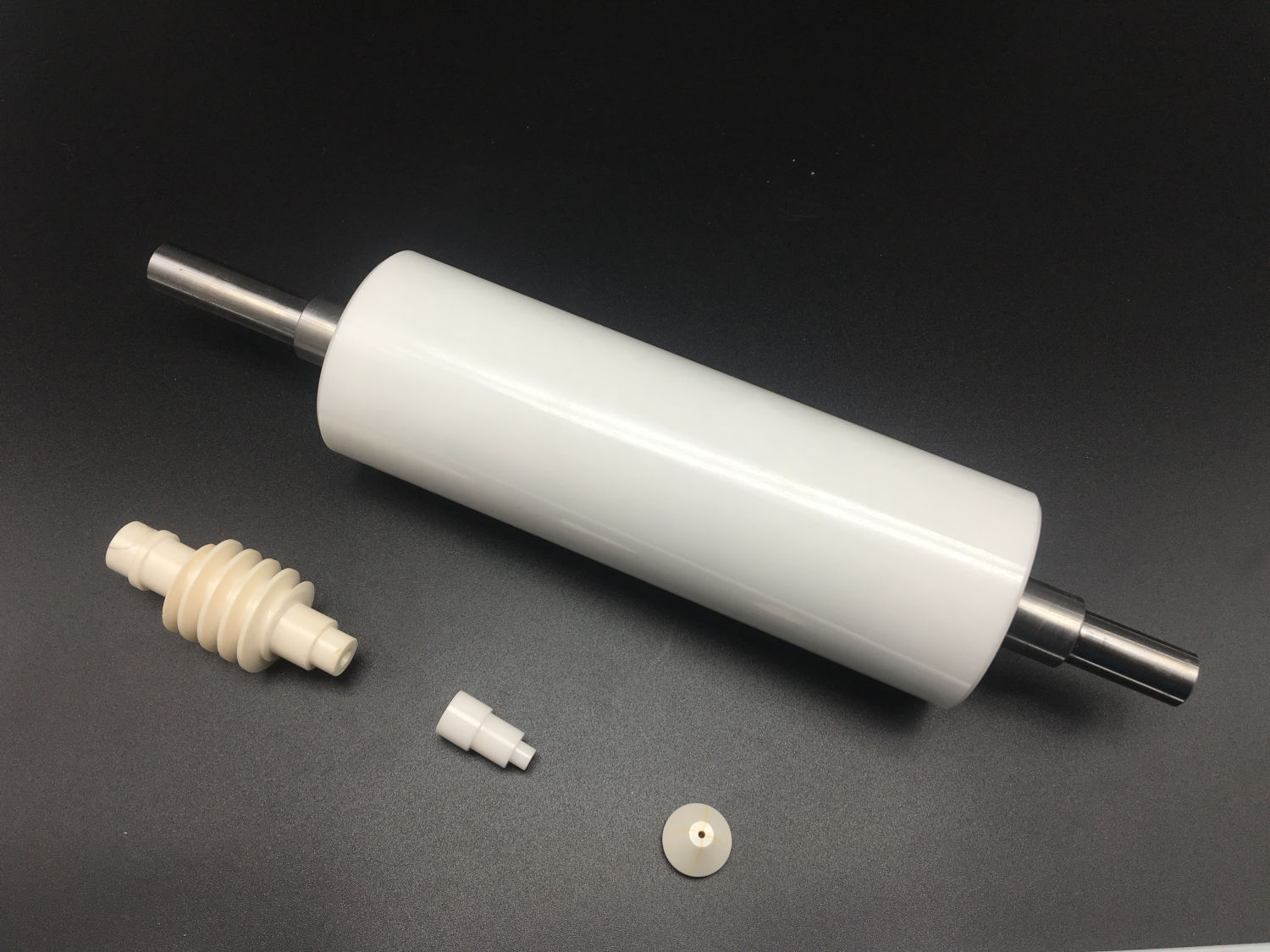

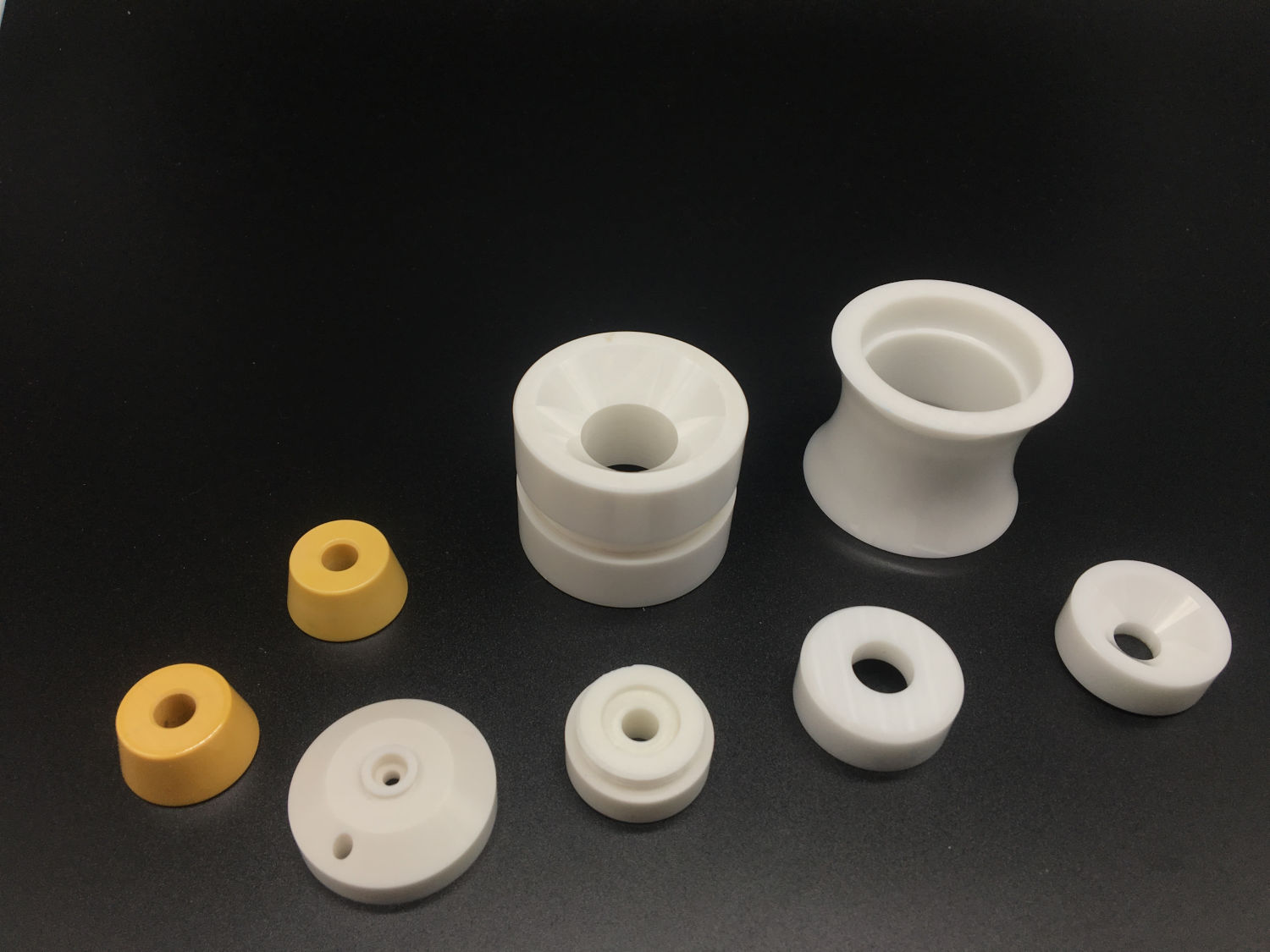

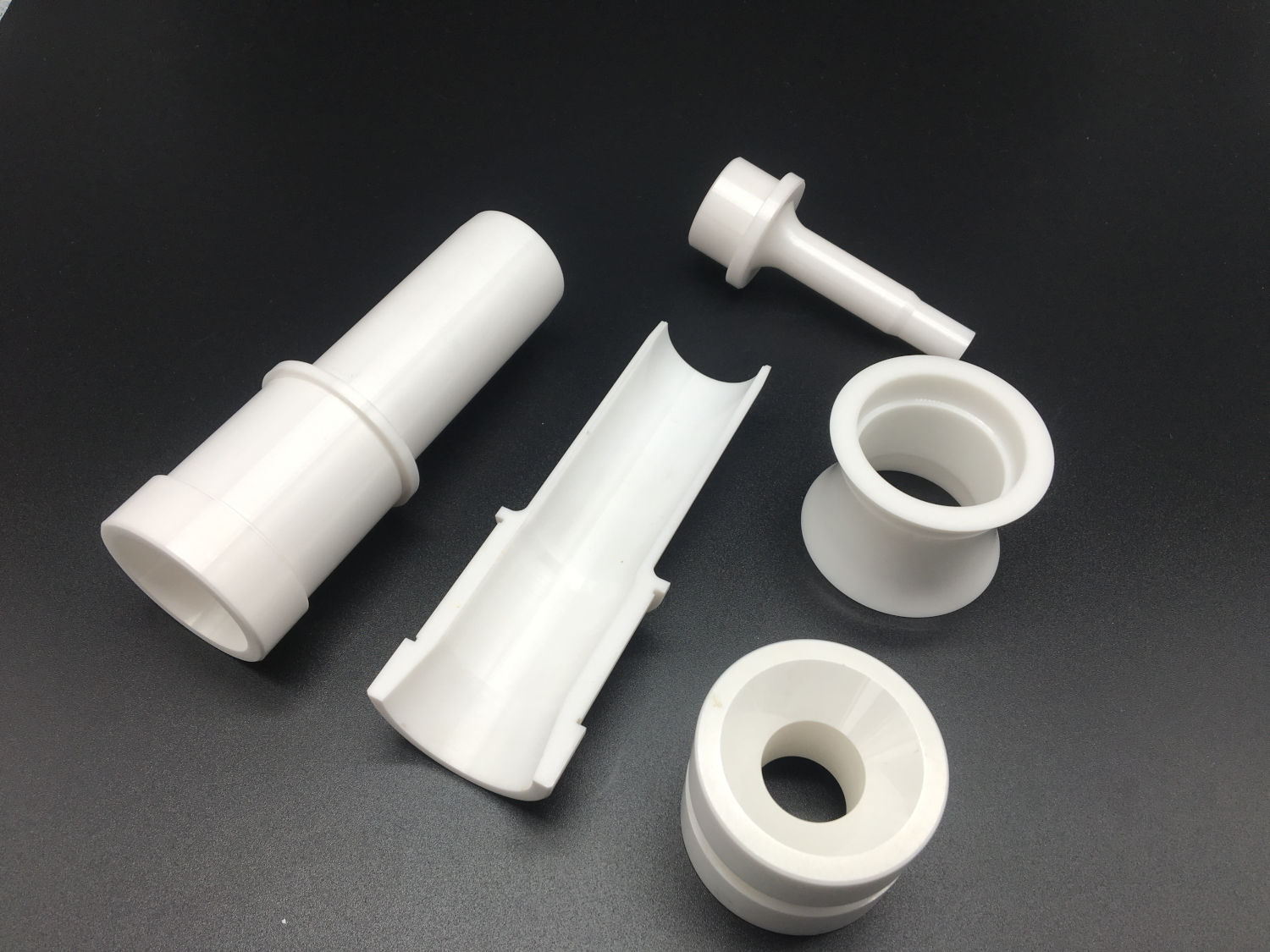

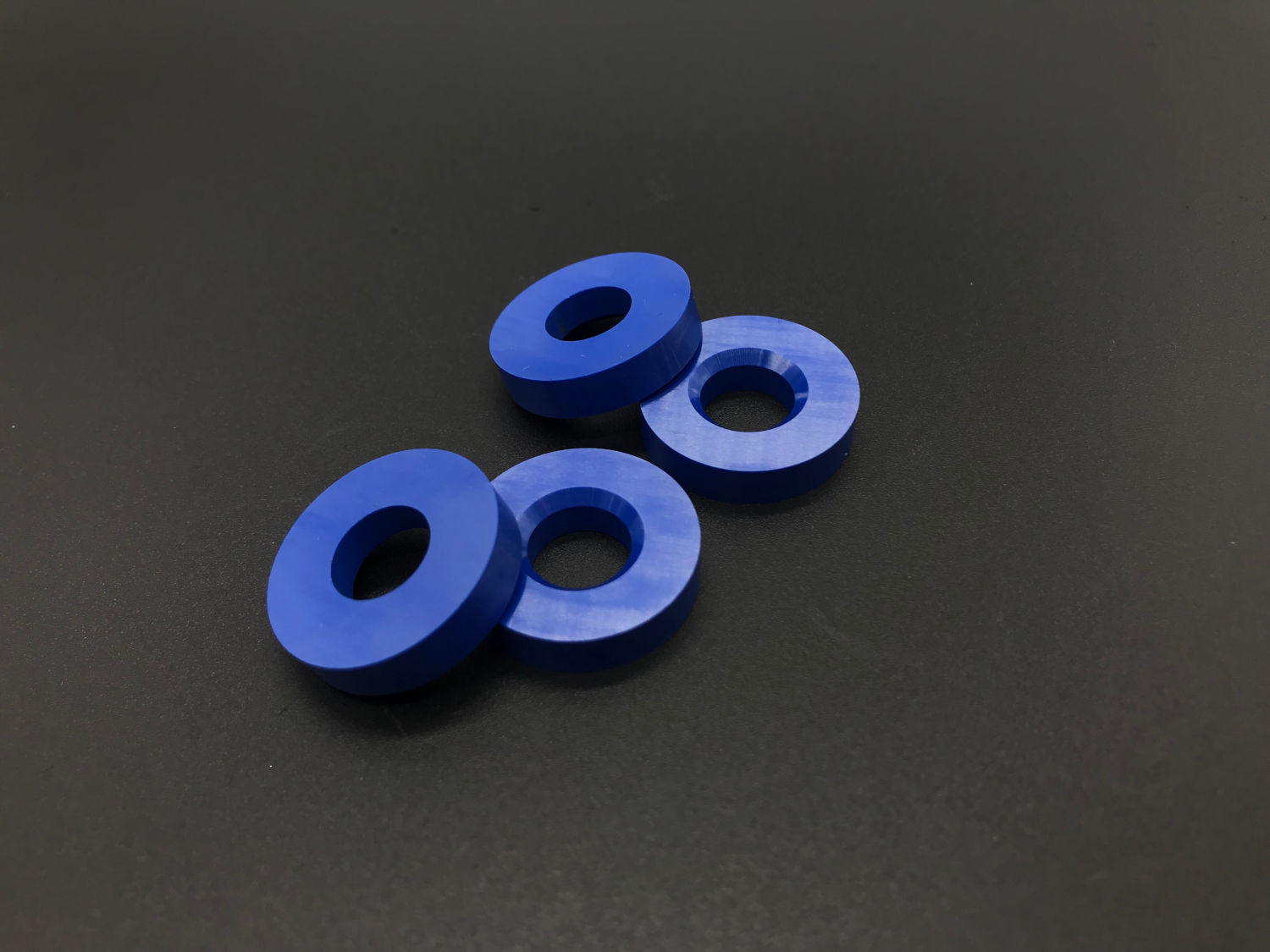

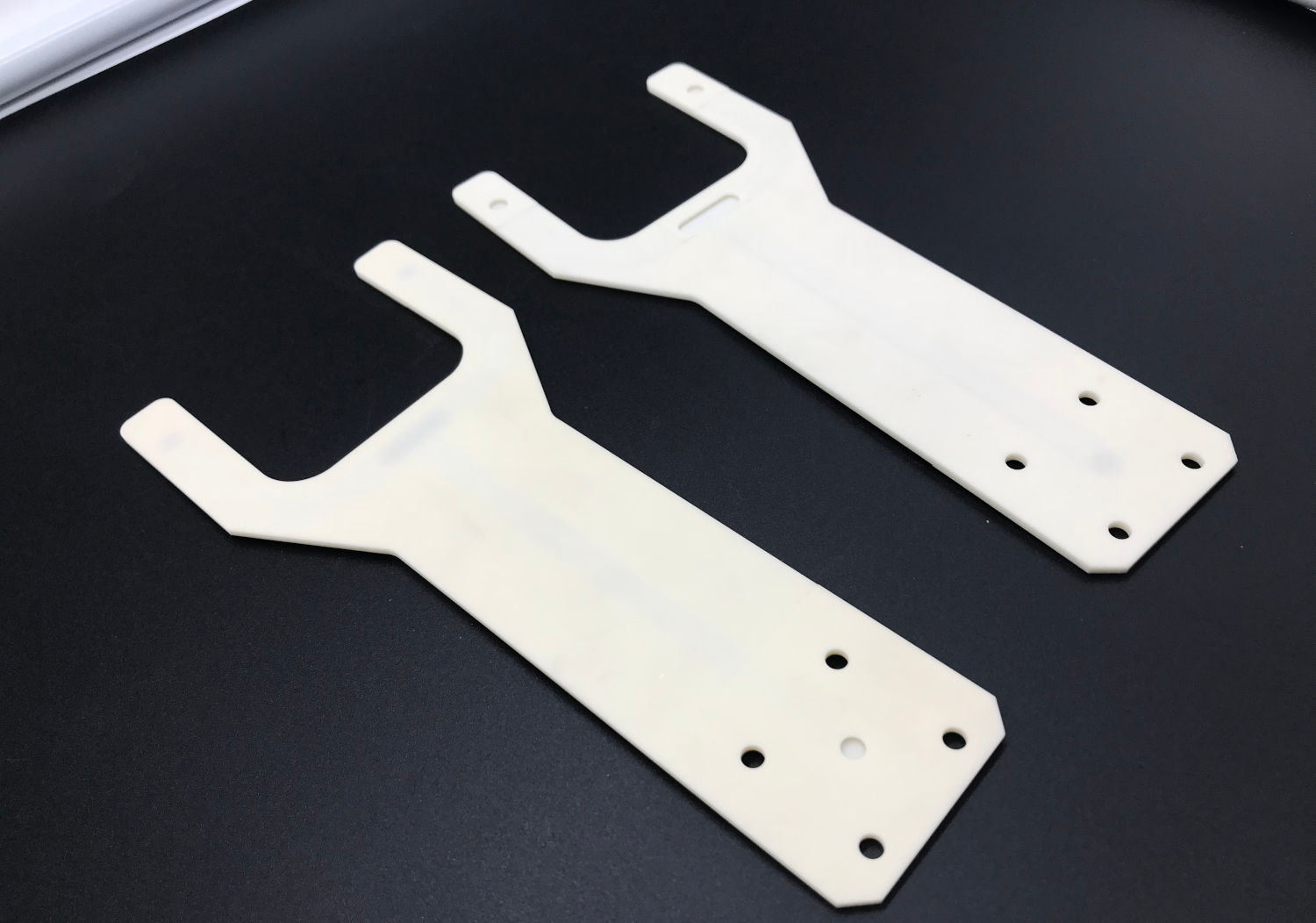

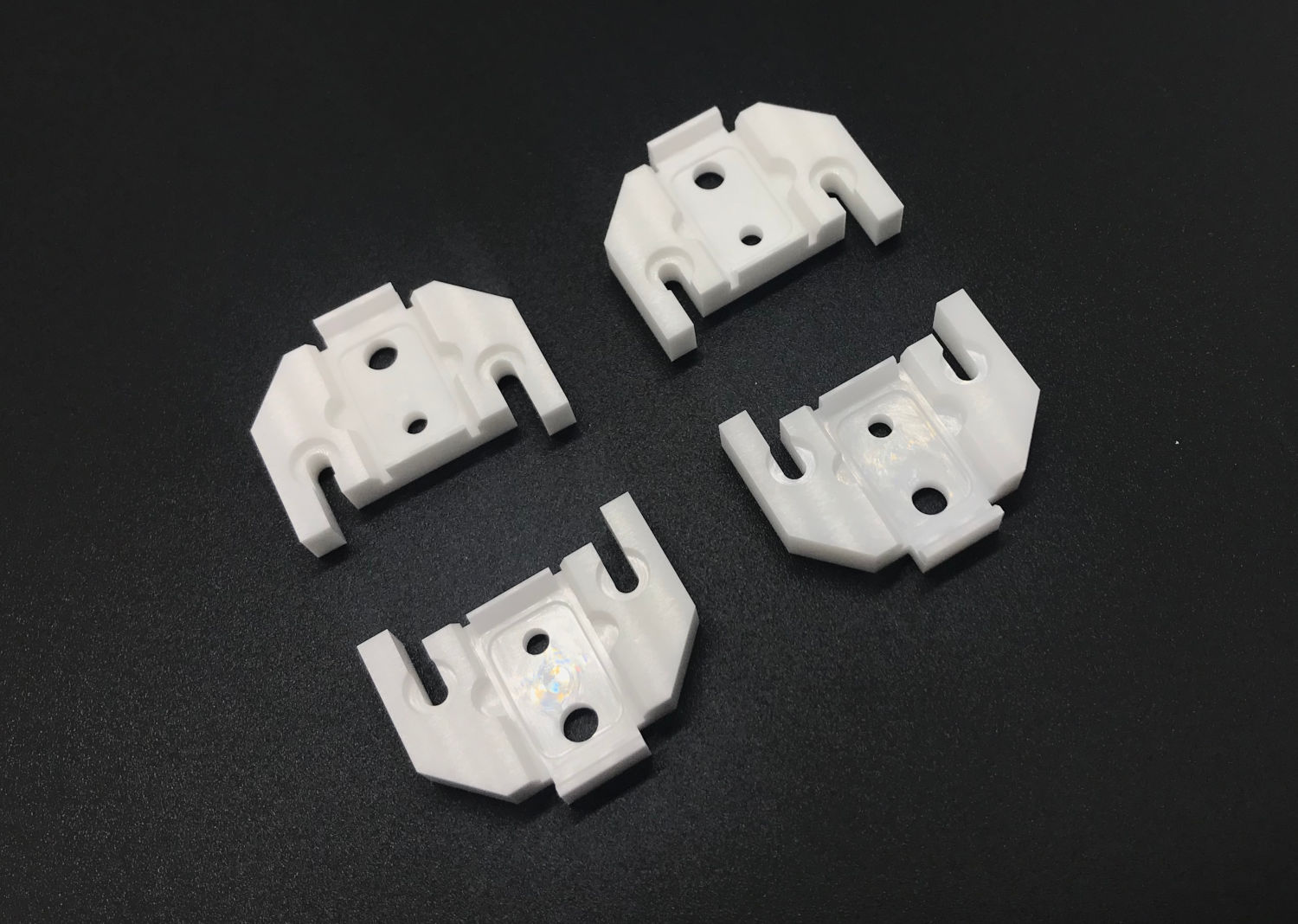

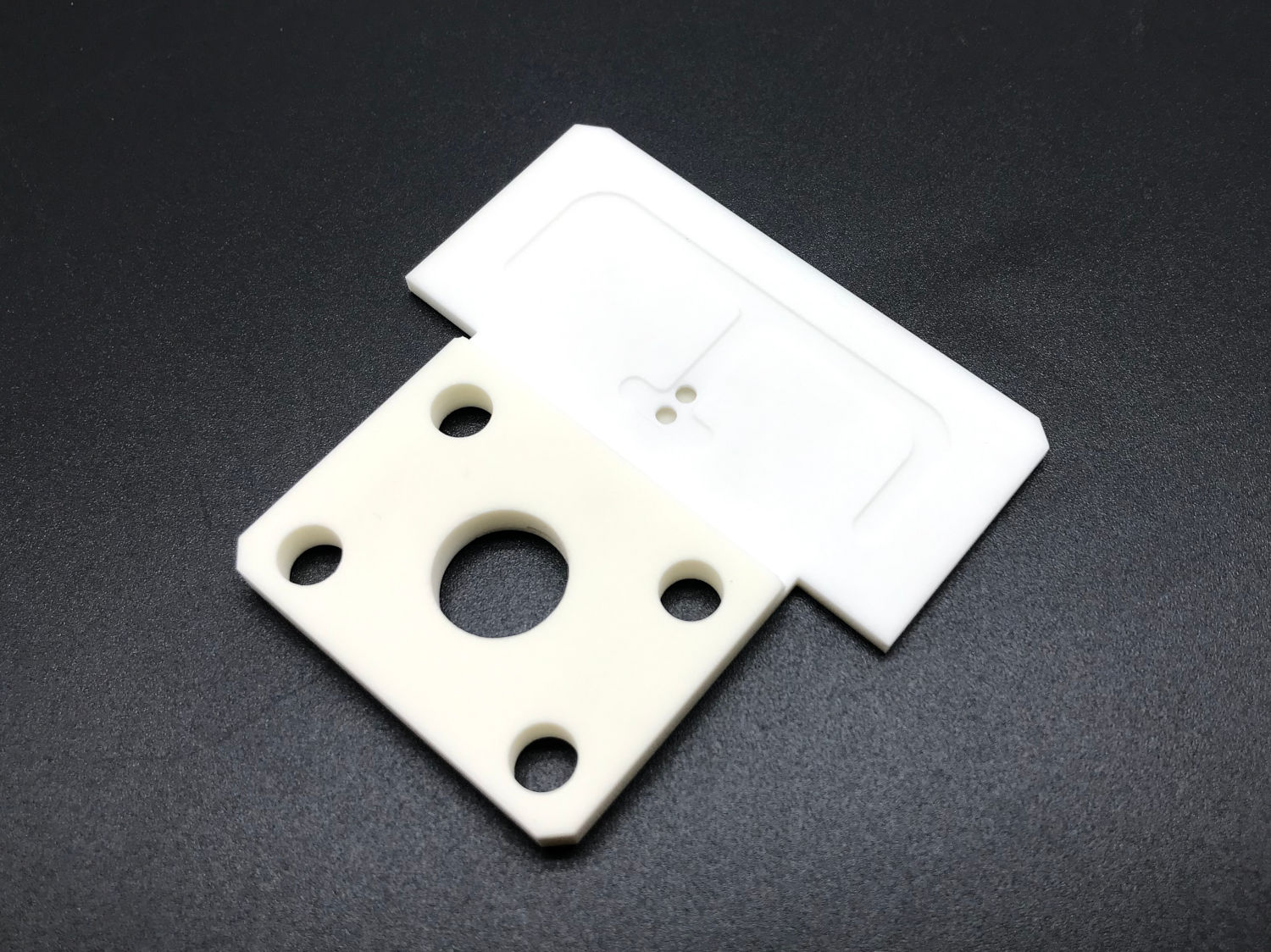

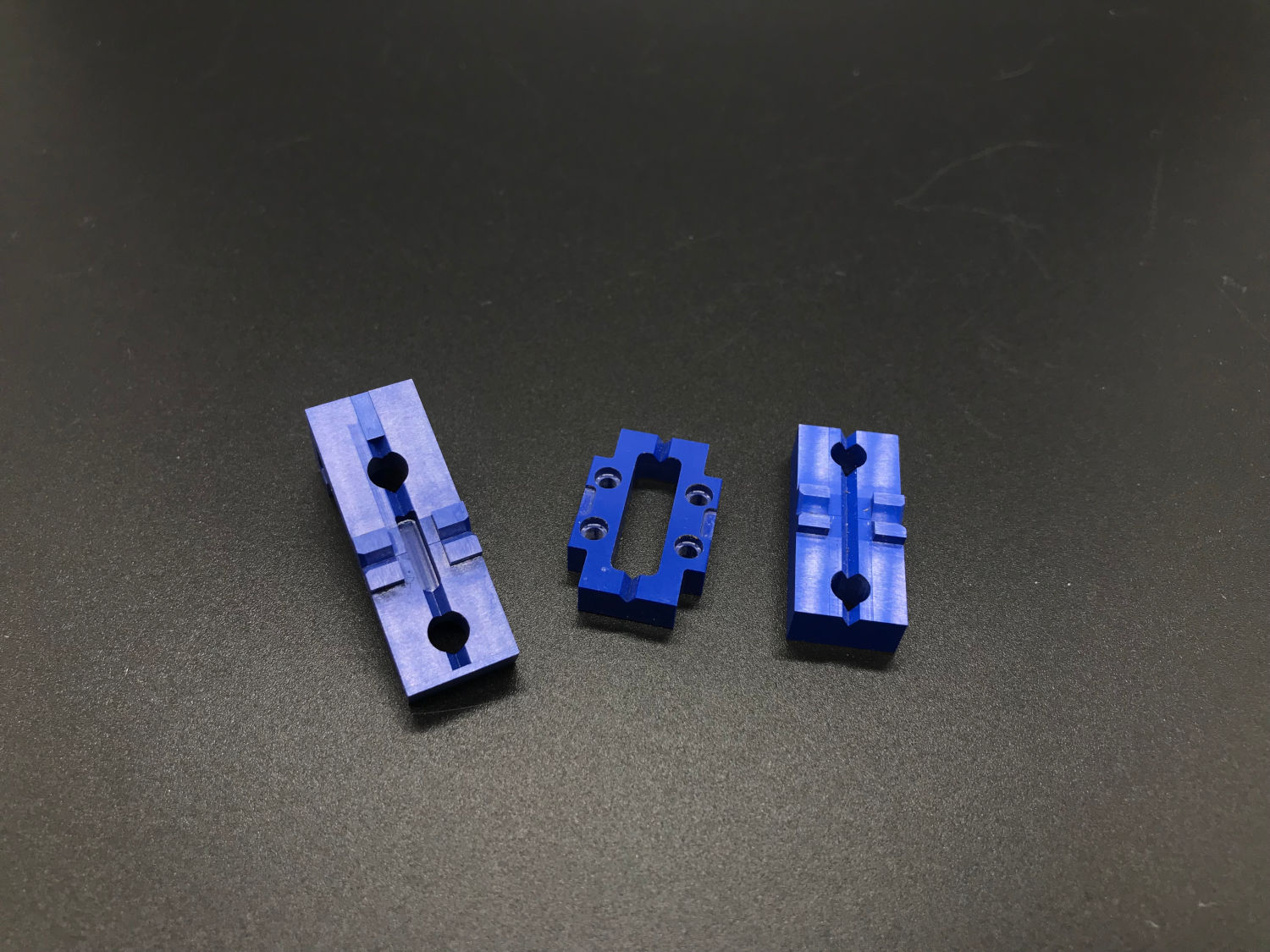

- Wear-resistant products: ball mill balls, ball mill columns, pipe linings, pipe linings, welding linings

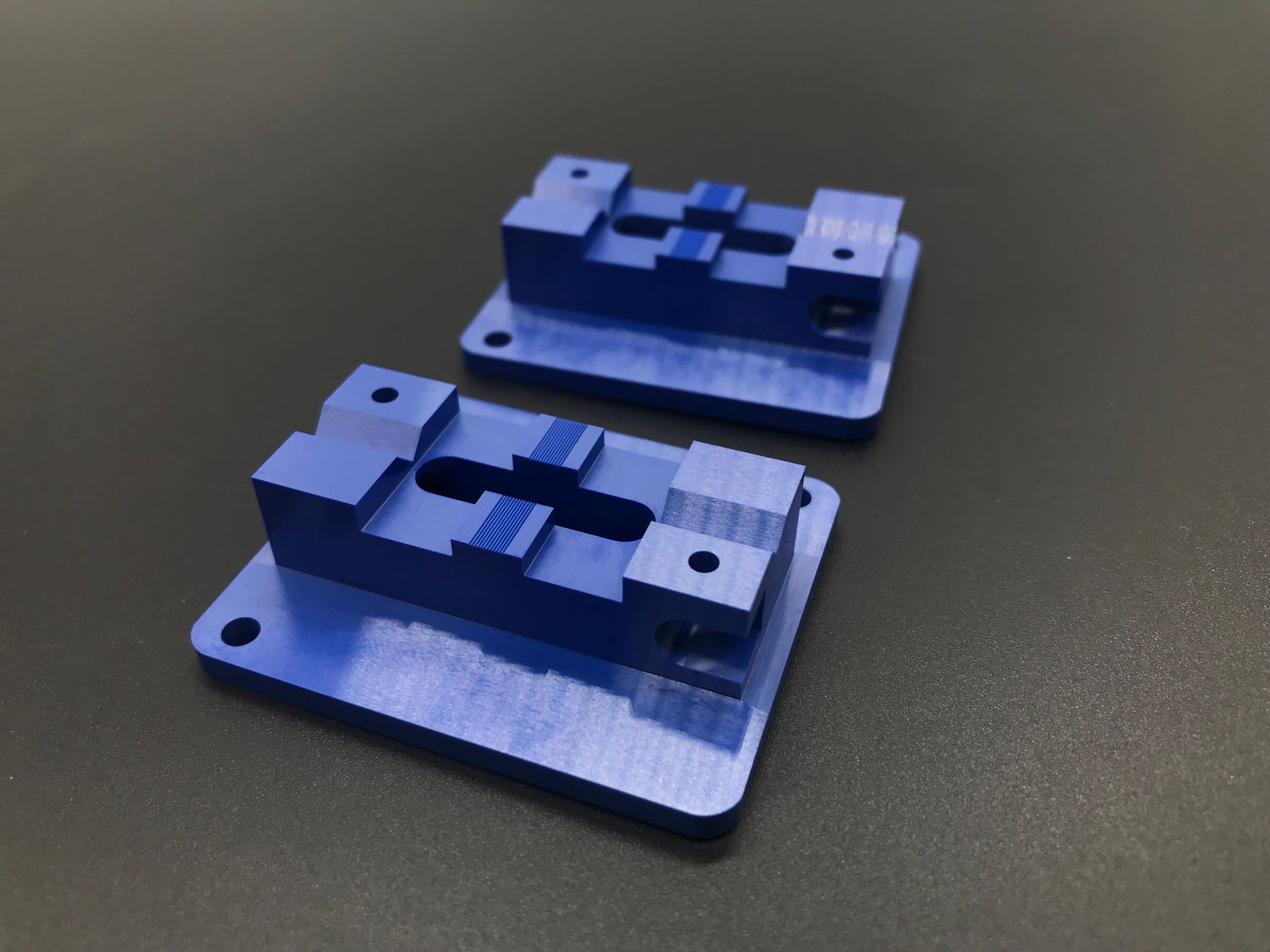

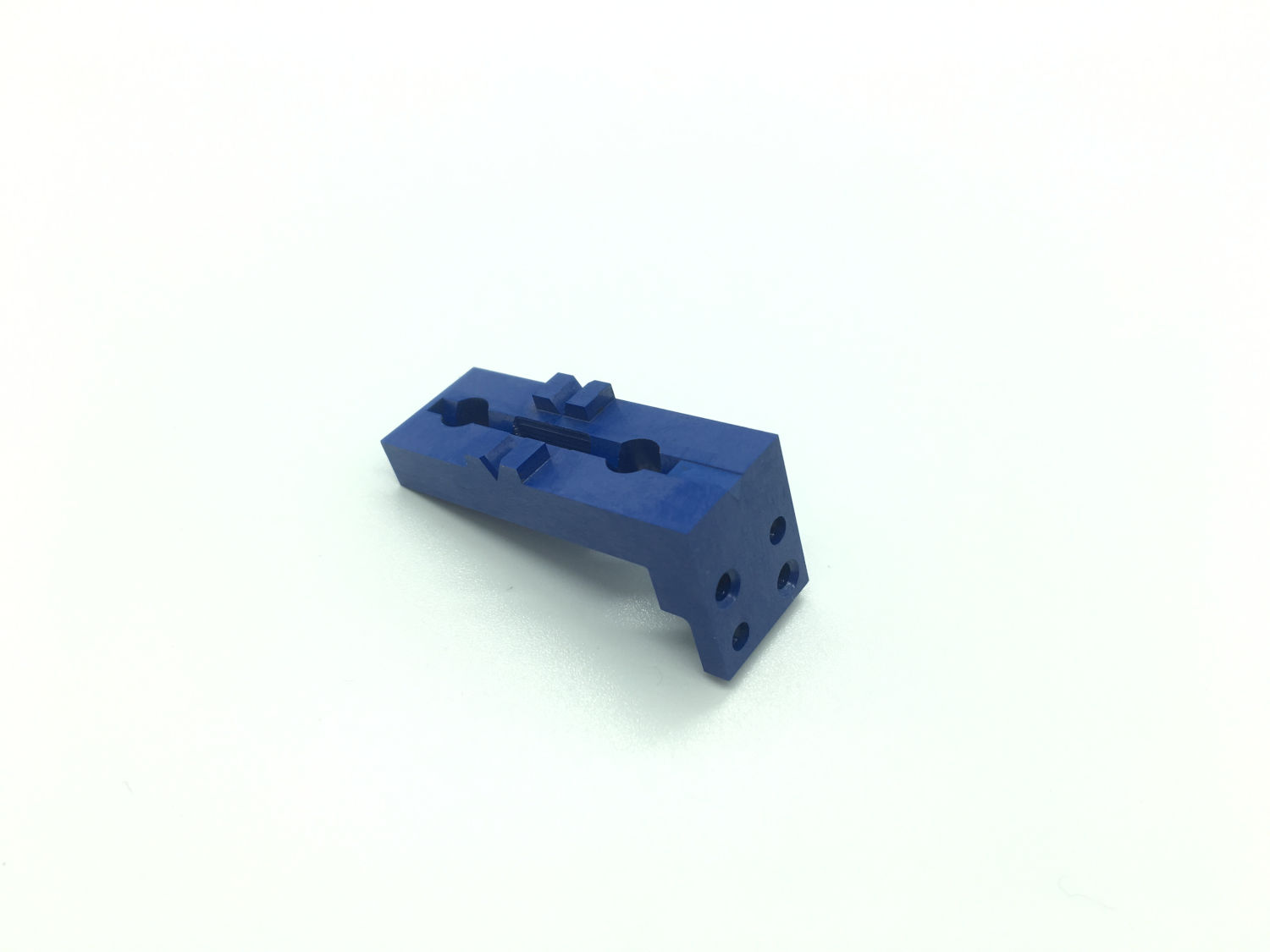

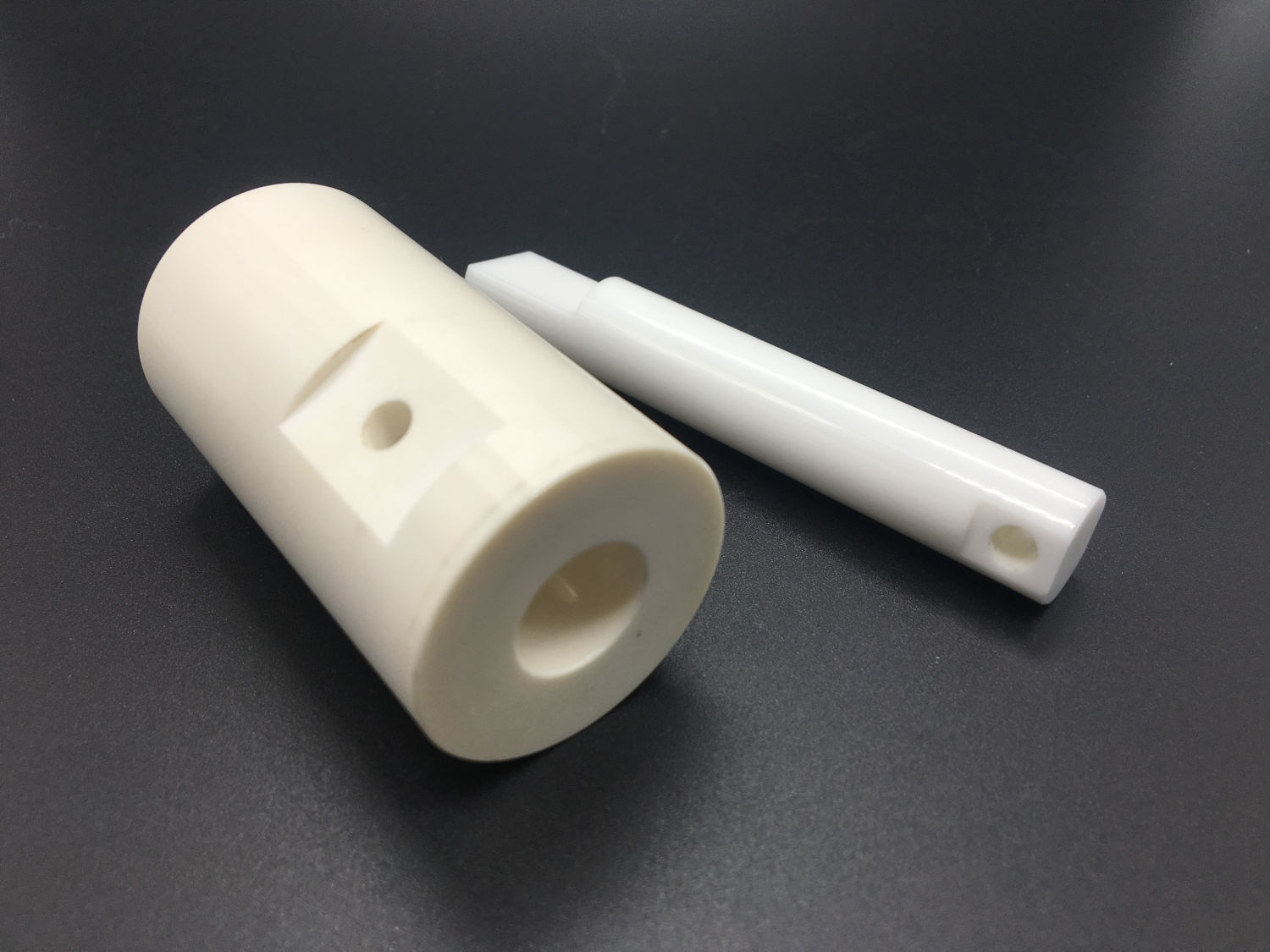

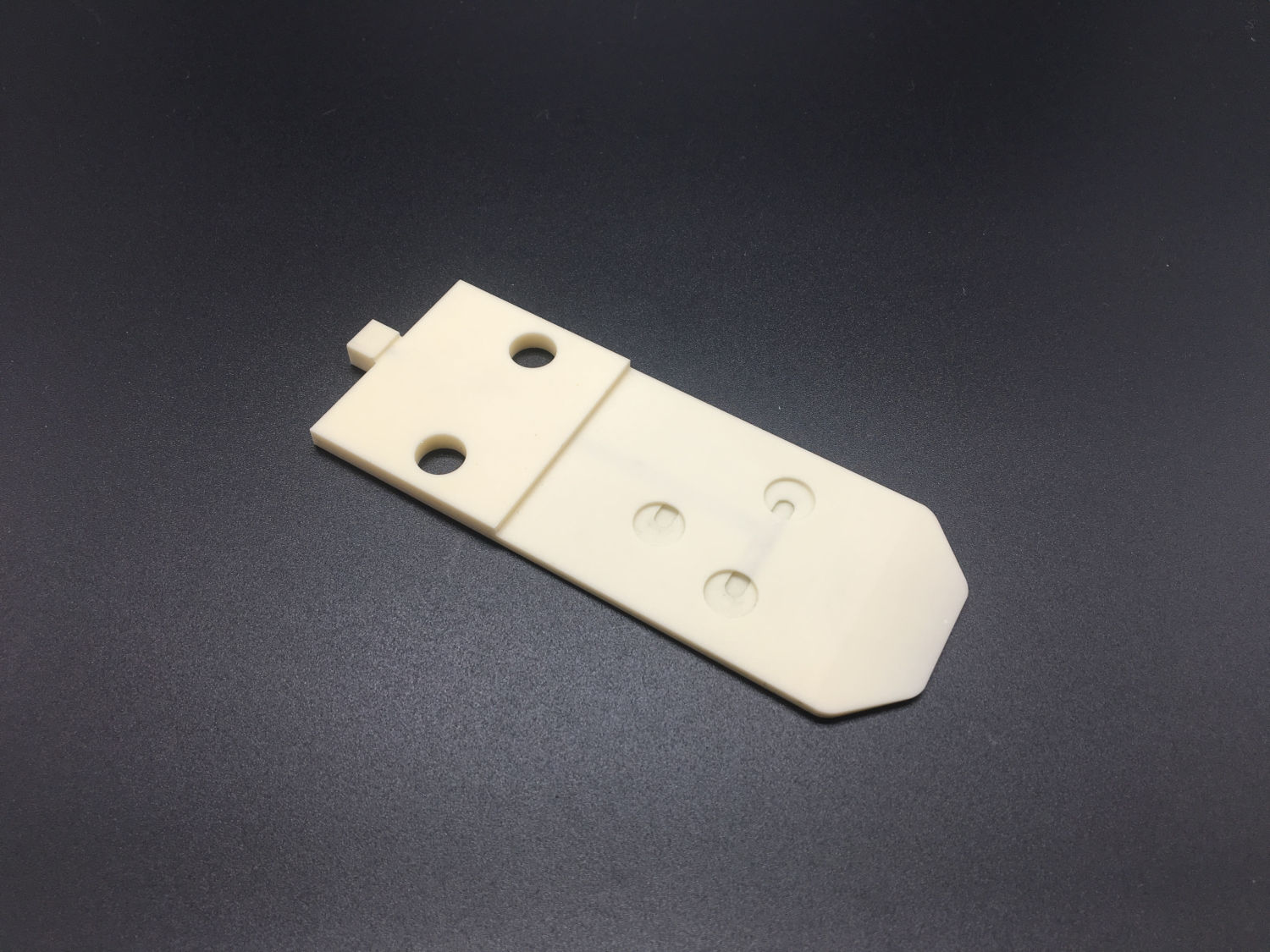

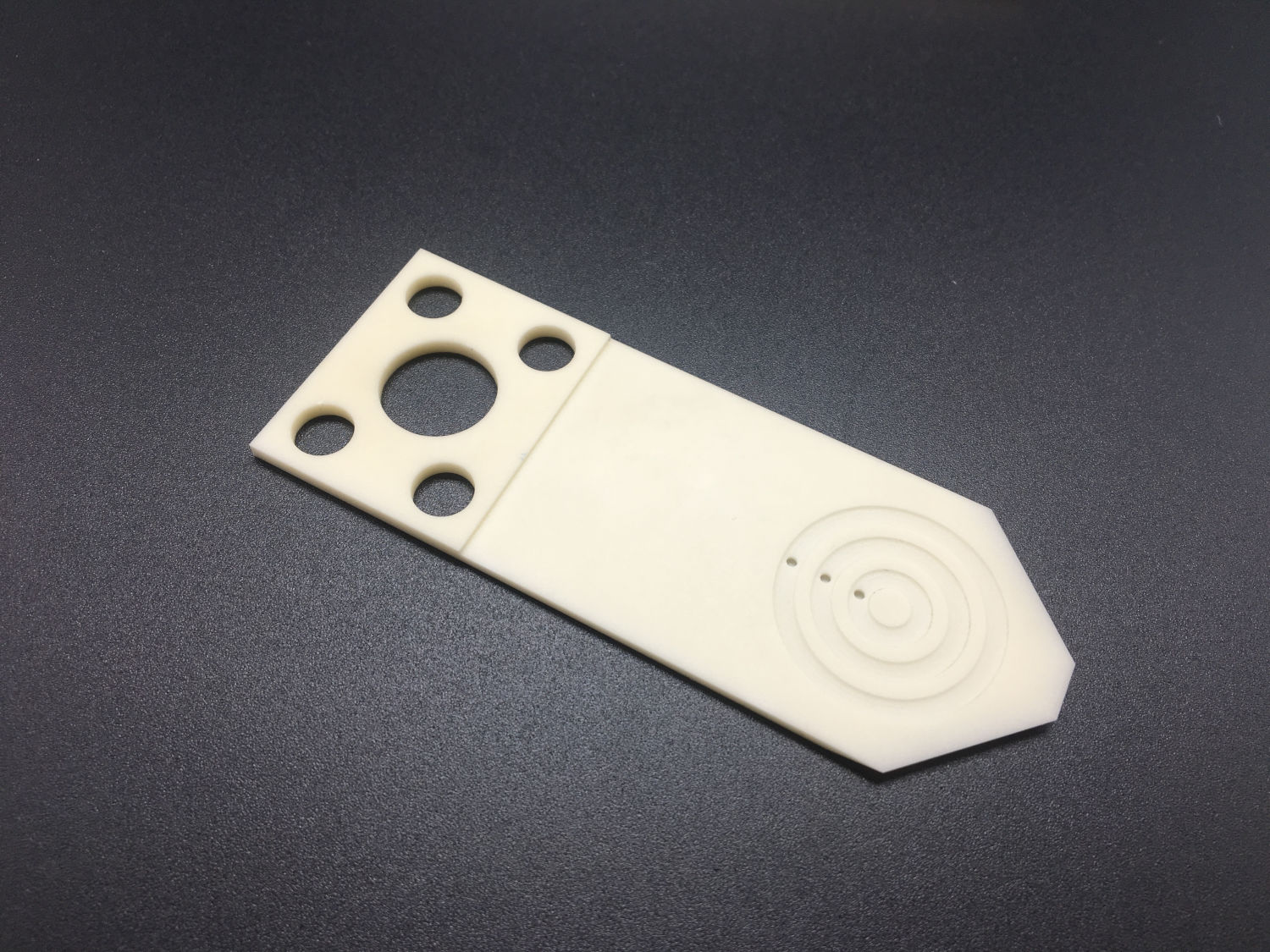

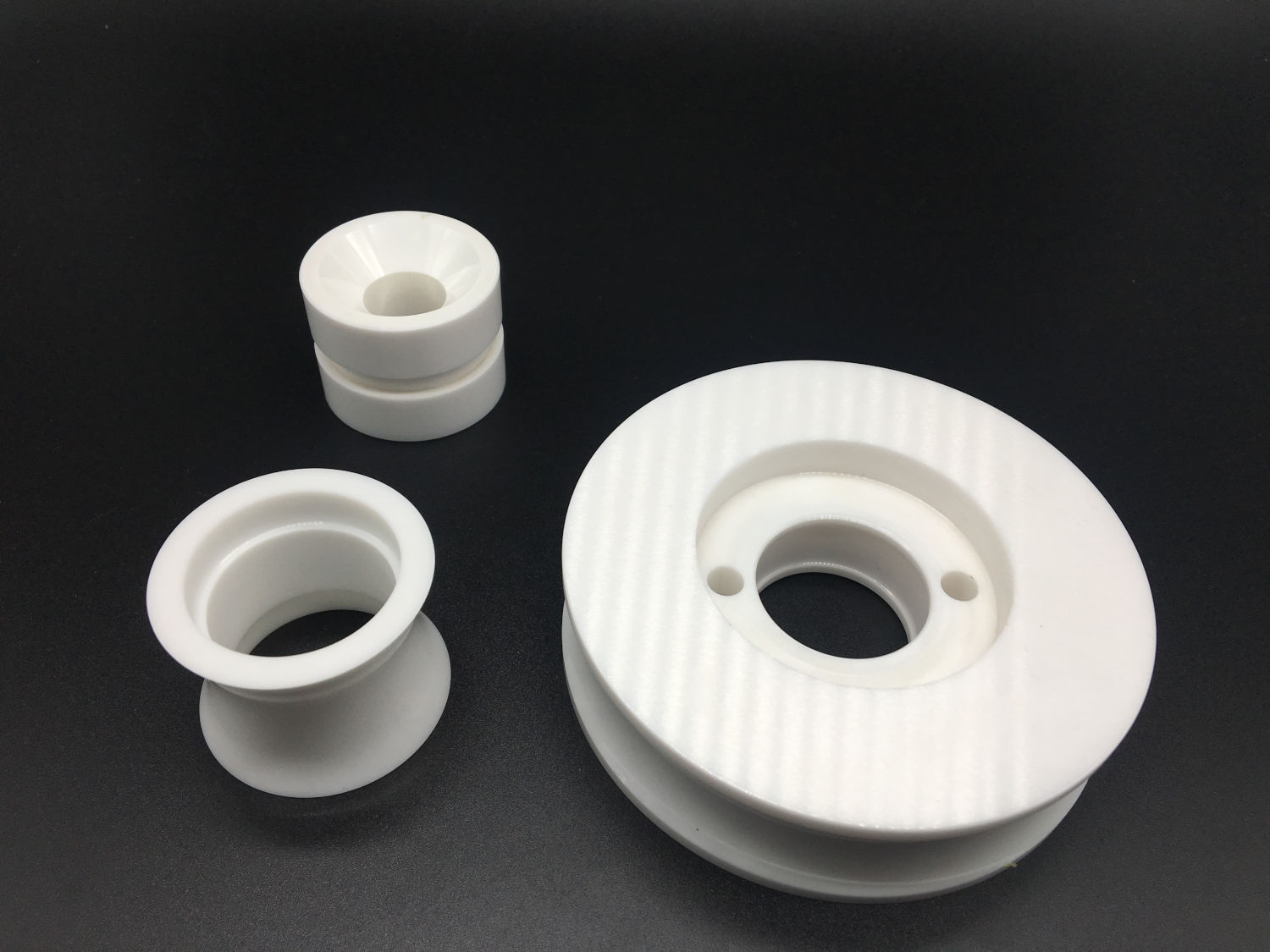

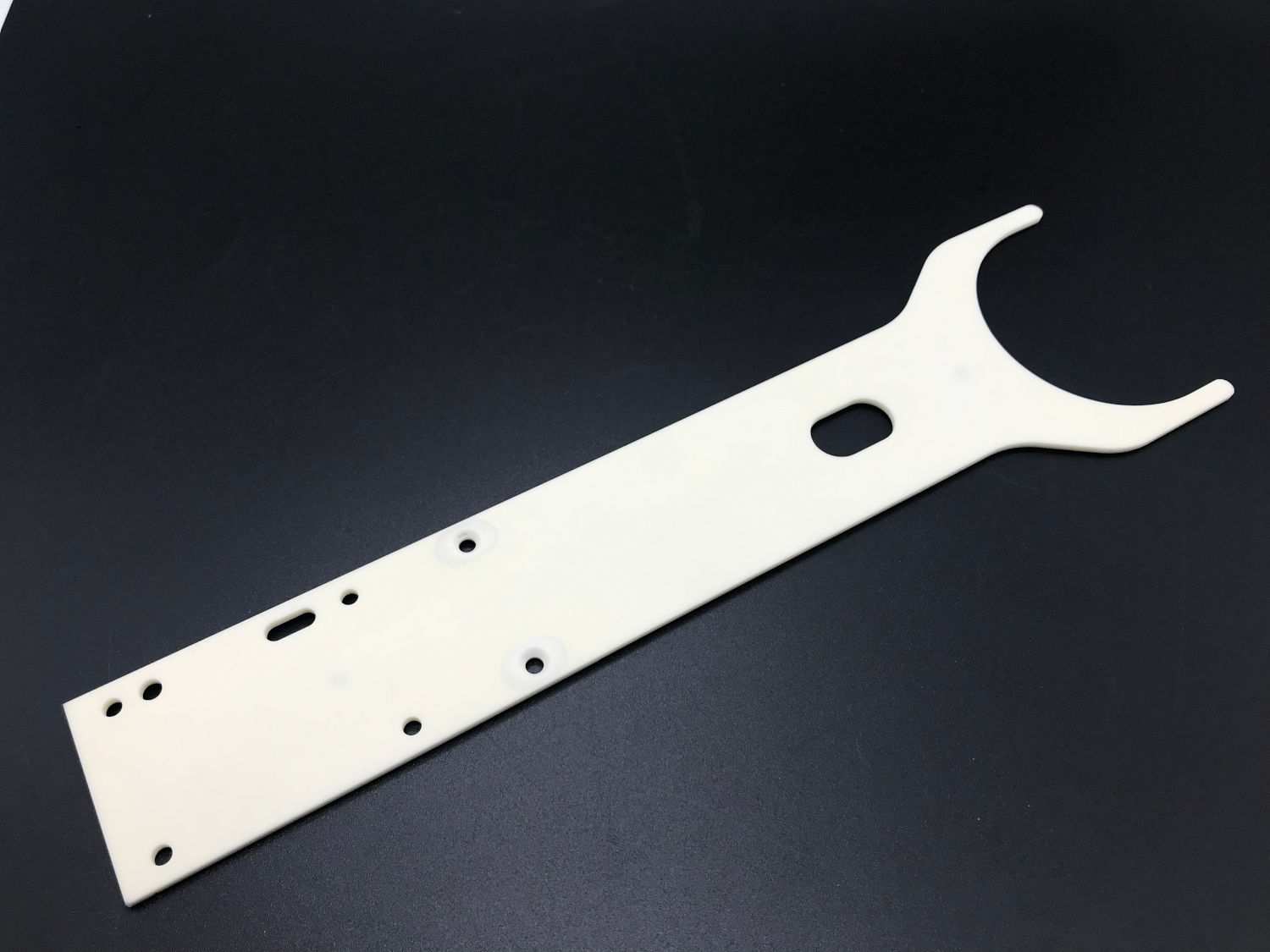

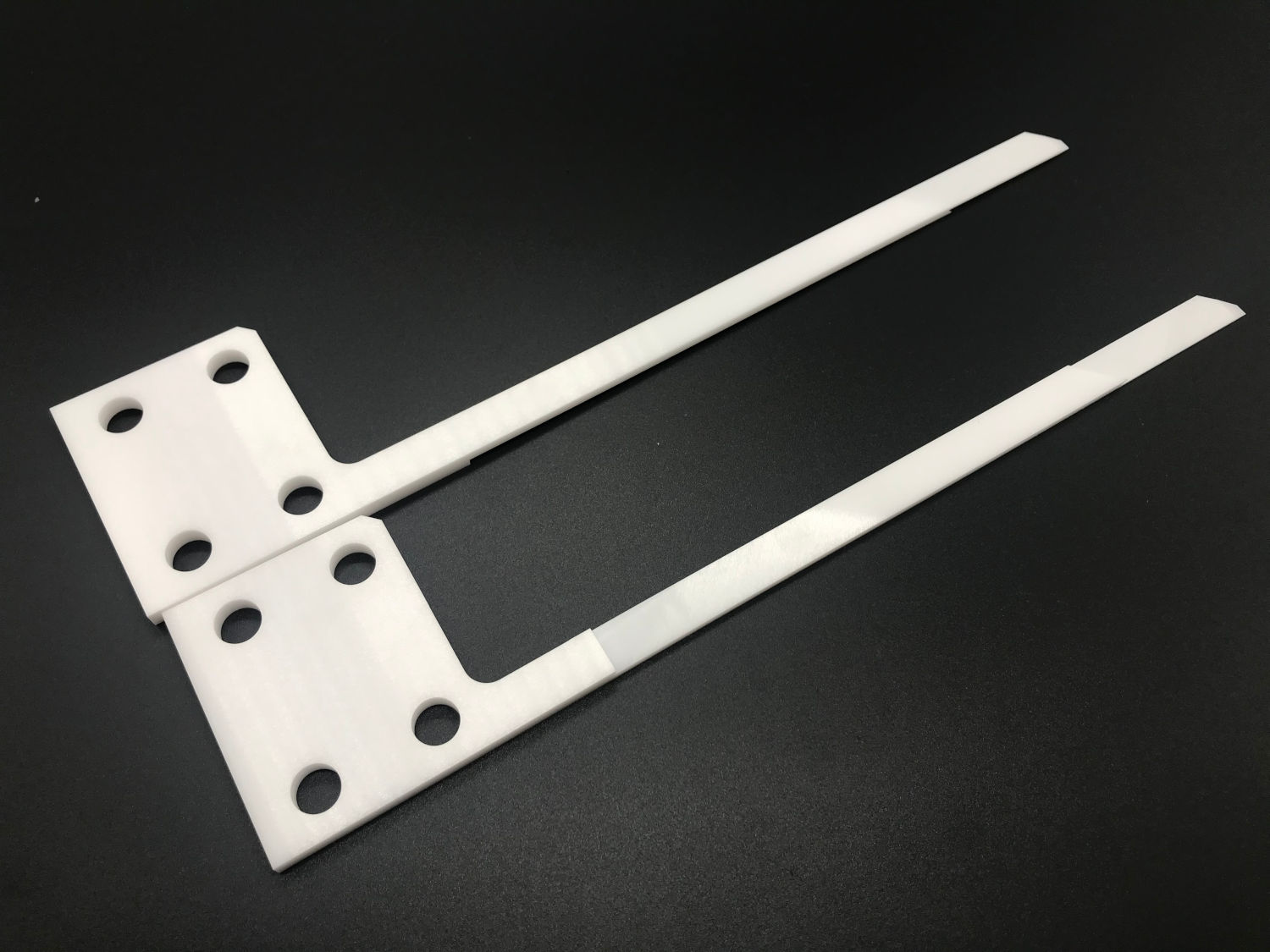

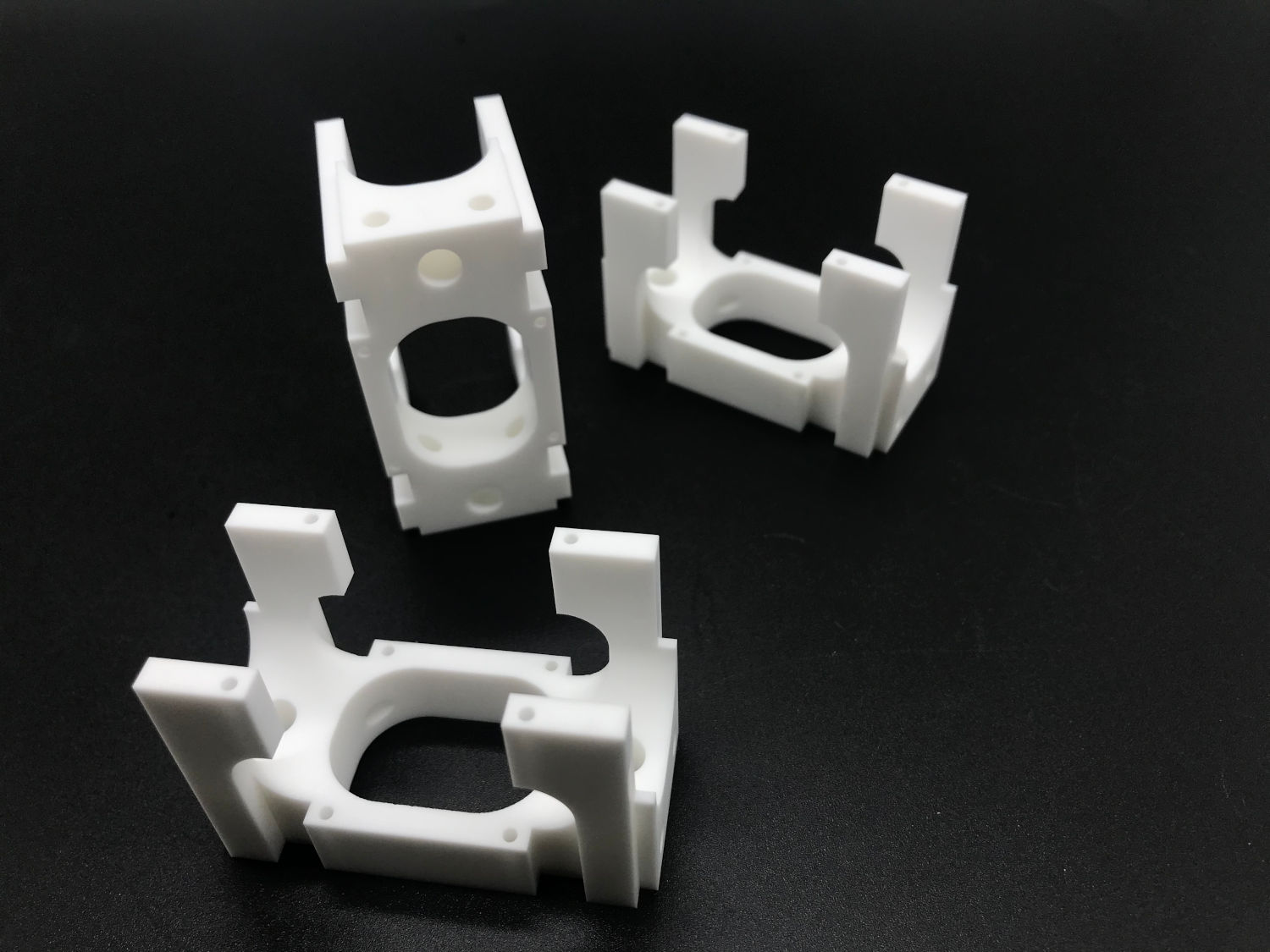

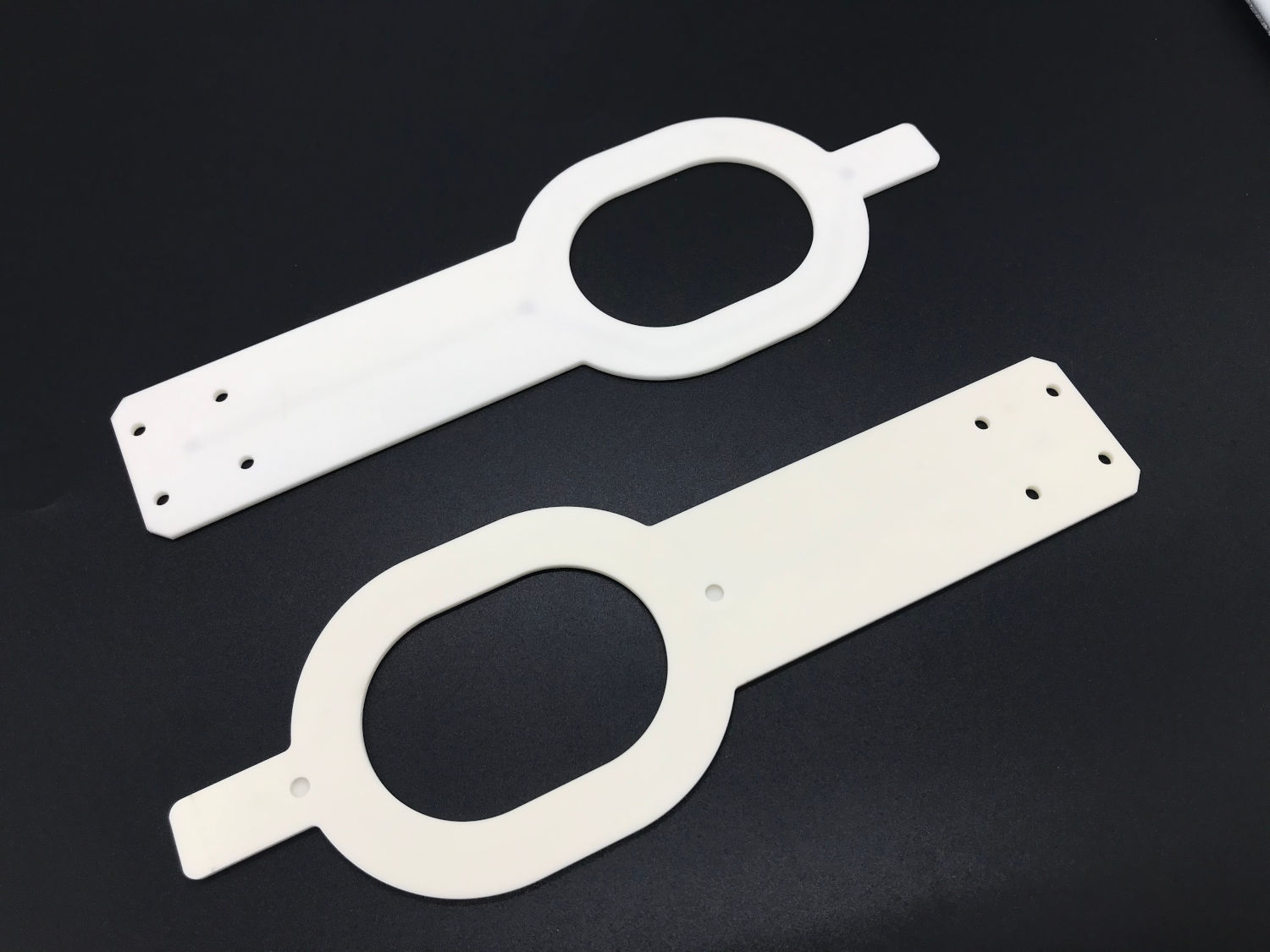

- Instrument accessories: sand mill accessories, crucible, robot arm, gasket, positioning piece, thermocouple protection tube

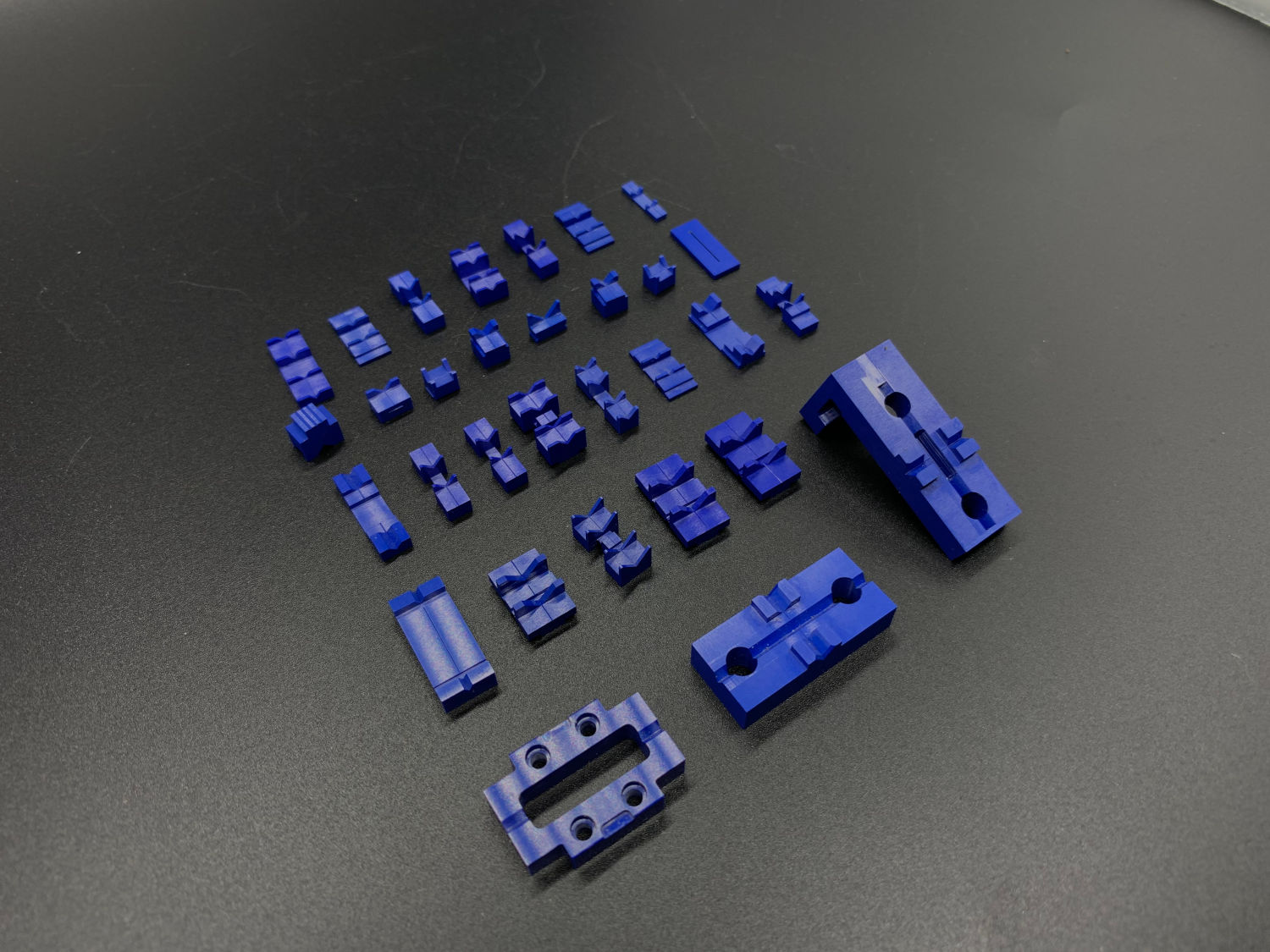

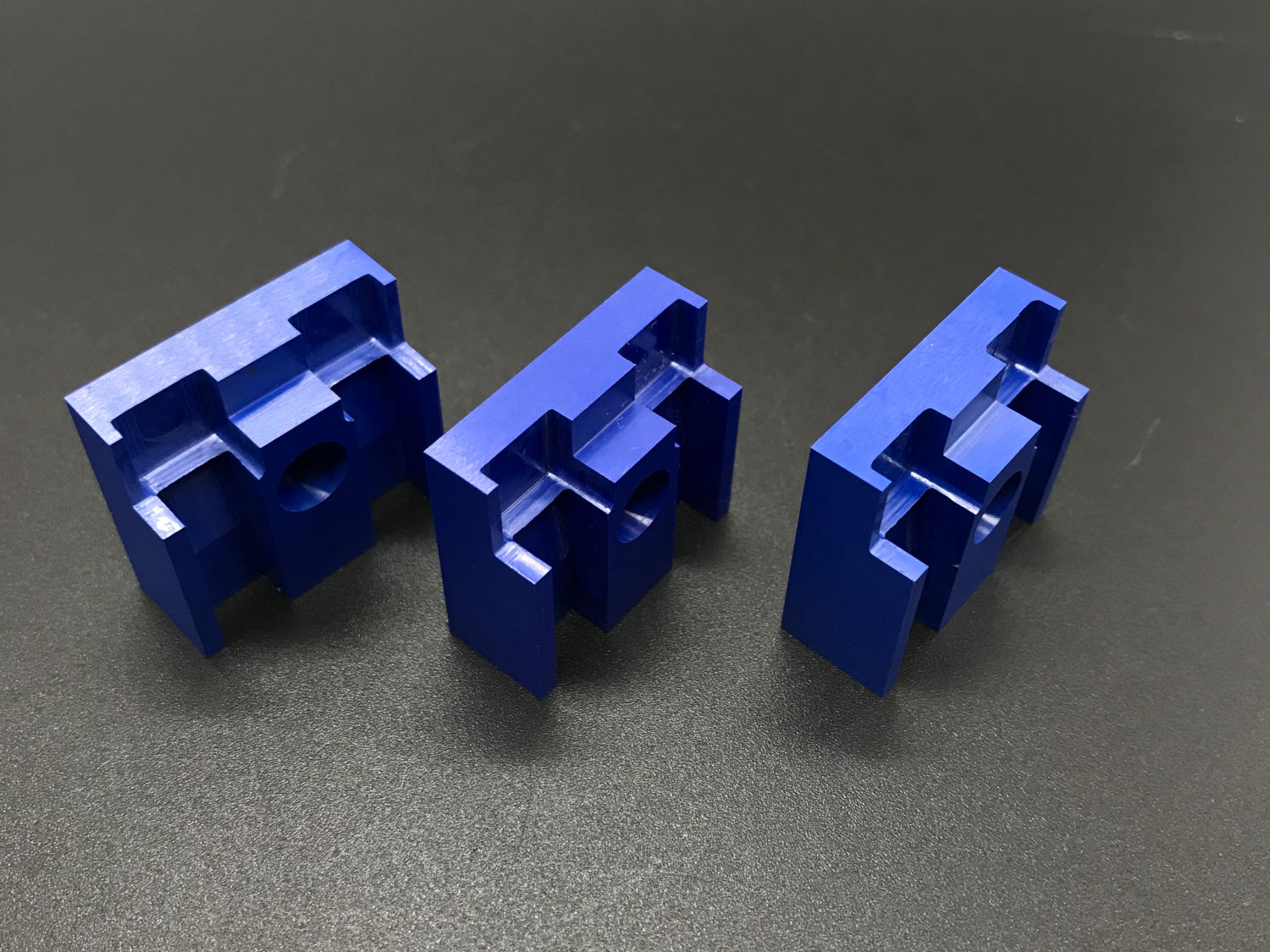

- Structural parts: welding positioning parts, ceramic ferrule, ceramic suction nozzle, precision roll, coil, vacuum chuck, positioning rod, bolt, various rods, tubes

- Electronic insulation: insulation pillars, electronic substrates, and insulation conduits

Advantages

- High mechanical strength

Zirconium oxide ceramic exhibits excellent mechanical properties such as high fracture toughness and hardness. It’s the material of choice for many biological applications or instruments in extreme conditions.

- Superior wear and corrosion resistance

This characteristic makes zirconium oxide ceramic the material of choice for grinding, milling media applications.

- Very good thermal insulation with low thermal conductivity

Zirconium oxide ceramic is used as high performance insulating materials for many thermal / mechanical processing.

Technical Characteristics – Zirconium Oxide (ZrO2)

| Y-PSZ | M-PSZ | |

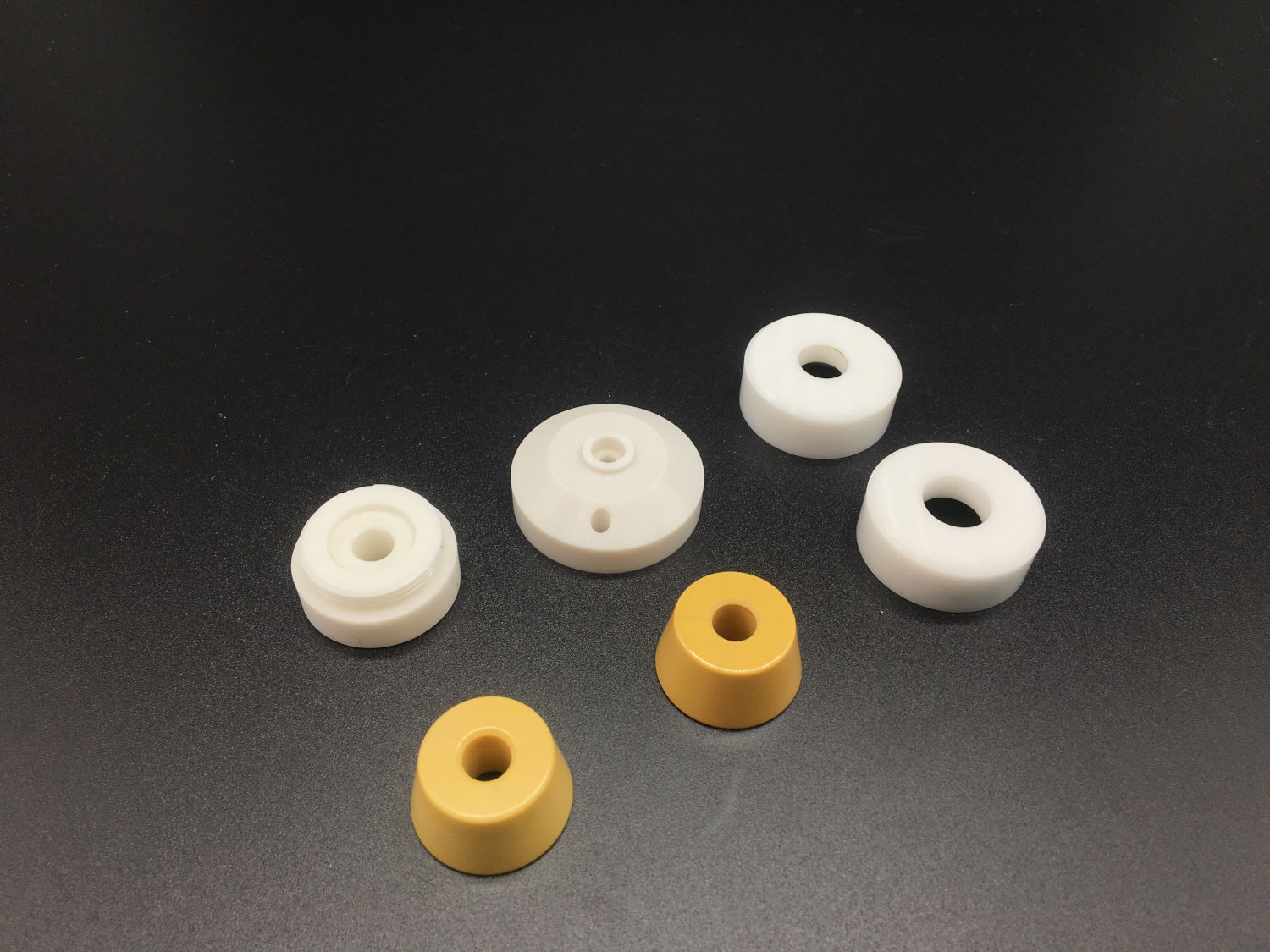

| Color | White | Yellow |

| Stabilizer Content (%) | 3mol | 9mol |

| Crystalline Phase | Tetragonal | Tetragonal |

| Water absorption (%) | 0 | 0 |

| Bulk density (g/cm3) | 6.0 | 5.7 |

| Thermal expansion (×10-6/℃) | 10.4~10.6 | 10 |

| Thermal conductivity(W/m·K) | 2.5 | 2 |

| Thermal shock resistance (Δ℃) | 280~320 | 400 |

| Max operating temp (℃) | 950 | 1000 |

| Compressive strength (MPa) | 2800 | 2500 |

| Flexural strength (MPa) | 970 | 620 |

| Vickers harness (HV0.5) | 1200 | 1100 |

| Fracture Toughness(MPa·m1/2) | 8~10 | 6~7 |

| Elastic Modulus (GPa) | 200 | 250 |

| Volume resistivity (Ω·cm) | >1013 | >1014 |

| Dielectric Constant (1MHz,25℃) | 33 | 28 |

| Dielectric Constant (V/m) | 11*106 | 13*105 |